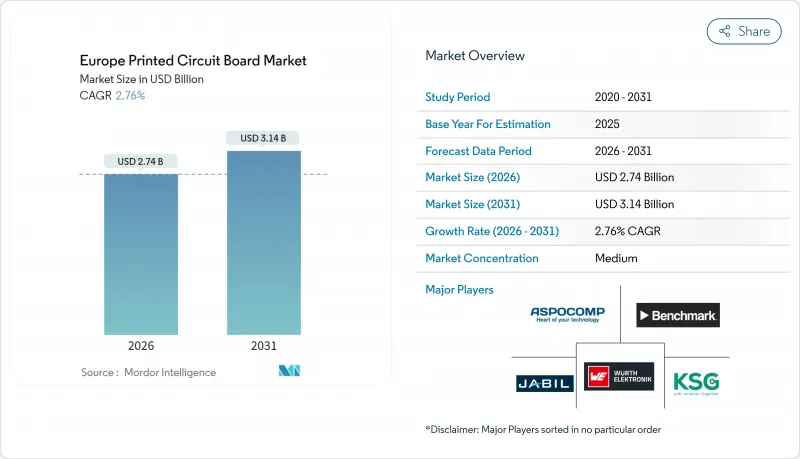

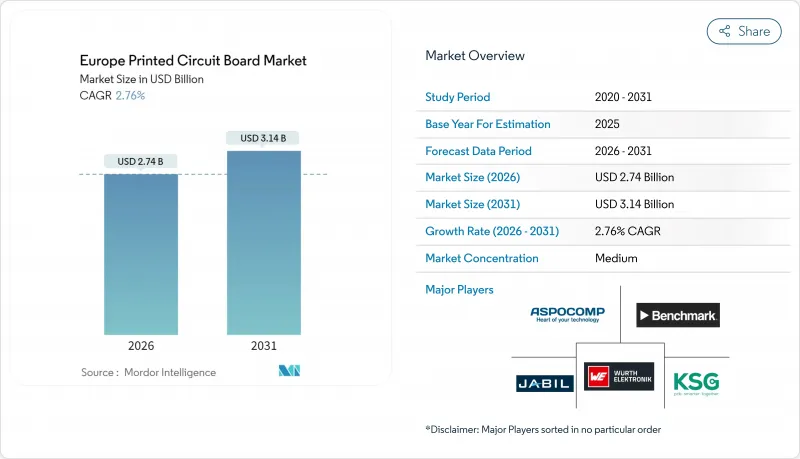

유럽의 인쇄회로기판(PCB) 시장 규모는 2026년 27억 4,000만 달러로 추정됩니다. 이는 2025년 26억 7,000만 달러에서 성장한 수치이며, 2031년에는 31억 4,000만 달러에 달할 것으로 예측되고 있습니다. 2026년부터 2031년까지는 CAGR 2.76%를 나타낼 전망입니다.

이 성장 궤적은 상용화된 대량 생산에서 프리미엄 가격 설정을 지원하는 자동차, 의료 및 산업 자동화 분야에서 규제 대상의 고부가가치 틈새 시장으로의 전략적 전환을 반영합니다. 유럽의 인쇄회로기판(PCB) 시장은 유럽 연합(EU)의 430억 유로(486억 달러) 규모의 '칩스법'에 의한 경기 자극책의 혜택을 받고 있습니다. 이 법은 반도체 팹, 고급 패키징 기지 및 관련 상호 연결 공급업체에 대한 투자를 촉진하는 것입니다. 공급망의 안전 보장, 규제 적합성, 까다로운 OEM 제조업체에 대한 지리적 근접성은 생산량이 전 세계의 2% 미만임에도 불구하고 지역 주문을 지속적으로 강화하고 있습니다. 저비용의 아시아 제품에 의한 경쟁 압력은 계속되고 있지만, 유럽 기업은 HDI 분야에서의 리더십, 엄격한 품질 관리 프로그램, 전문적인 설계 서비스를 통해 이익률의 압박을 완화하고 있습니다. SOMACIS의 의료 등급 제품 인수와 시코르의 기록적인 수주 증가가 보이는 것처럼 통합이 진행됨에 따라 유럽의 인쇄회로기판(PCB) 시장은 더욱 명확해지고 있으며, 잔존 기업들 사이에서는 규모 확대 또는 전문화로의 이행이 진행 중임을 알 수 있습니다.

소형화 및 경량화에 대한 끊임없는 추구로 OEM 제조업체는 HDI 및 울트라 HDI 기판을 지정할 수 없었으며, 유럽의 인쇄회로기판(PCB) 시장은 마이크로비아 제조에서 주도적인 역할을 담당하게 되었습니다. 지역 공급업체는 현재 50마이크로미터의 도체 폭과 75마이크로미터 미만의 마이크로비아 인증을 받았으며, 신호 무결성을 향상시킨 다층 적층 구조로 기존의 관통 구멍 설계를 대체할 수 있게 되었습니다. 레이저 드릴링 플랫폼, 개선된 세미 애디티브 프로세스, 엑스레이 검사에 대한 투자는 이러한 능력을 지원하고 있으며, NCAB 그룹과 오스트리아 전문 제조업체들은 2025년을 통해 공장 가동 준비 프로그램을 가속화했습니다. 이로 인해 유럽의 인쇄회로기판(PCB) 시장은 가격 경쟁을 억제하는 기술적 차별화를 통해 탄력성을 얻습니다. 또한 자동차 및 의료 분야의 엄격한 기준은 공정 관리 및 추적 가능성을 문서화하는 생산자를 평가하고 HDI 생산에서 가치 창출을 강화합니다. 독일 자동차 클러스터에서 네덜란드의 산업용 IoT 허브로 채용이 확대되는 가운데 HDI 수요는 지역 수익 성장의 중기적인 상승 요인으로 지속됩니다.

2025년에 강화되는 유럽의 CO2 배출 규제를 배경으로 1월 단월에 배터리식 전기자동차 등록 대수가 전년 대비 21% 증가한 25만대 이상에 달하고, 차량 1대당 복잡한 다층 기판의 탑재량이 급증했습니다. 배터리 관리 시스템, 구동 인버터 및 ADAS 모듈은 현재 IPC-6012 자동차 표준 부록에서 인증된 엄격한 진동 및 열 사이클 요구 사항을 충족하는 8층 이상의 HDI 설계에 의존하고 있습니다. 그 결과 유럽의 인쇄회로기판(PCB) 시장은 독일, 프랑스, 이탈리아의 EV 공장 인근에서 저스트 인 타임 조립을 목적으로 지역 생산을 의무화하는 Tier 1 공급업체로부터 지속적인 주문을 보장합니다. 전기자동차 하위 부문은 자동차 분야에서 가장 높은 CAGR을 기록하고 있으며 2030년까지 지속적인 수량 견인 요인이 되는 것이 확실합니다. 공급업체는 긴 인증 사이클과 엄격한 결함 패널티를 활용하여 수입품에 대한 마진을 지키는 동시에 OEM과 협력하여 제약된 팩의 실적 내에서 기판 레이아웃과 전력 밀도의 공동 최적화를 진행하고 있습니다.

구리 가격은 2024년 5월에 톤당 1만 1,000달러를 웃돌았지만, 같은 해 후반에는 9,000달러를 밑돌았습니다. 조사에서는 전동화 수요에 의해 2025년 말까지 1만 달러를 넘는 회복을 보였습니다. 동은 원재료비의 40%를 차지하고 재료비가 총 비용의 약 40%를 차지하기 때문에 가격변동은 이미 높은 인건비·에너지 비용으로 고통받는 유럽의 팹 공장의 EBITDA를 직접 압박합니다. 적층기판 공급업체도 2024년의 감소 국면에서 두 자리수의 추가 요금을 밀어붙여 많은 기판 제조업체가 연간 가격의 재협상과 분기별 조정 조항의 적용을 강요받았습니다. 이러한 이유로 유럽의 인쇄회로기판(PCB) 시장은 위험 회피 프로그램이나 장기 공급 계약이없는 중소기업에 특히 심각한 영향을 미치는 이익률 변동에 직면하고 있습니다. 판매 가격에 차지하는 재료비 비율이 낮은 HDI 프로토타입에 특화함으로써 리스크를 경감하는 기업도 있고, 구리와 적층판의 지수를 실시간으로 재계산하는 동적 견적 소프트웨어를 도입하는 기업도 있습니다.

2025년 시점에서 HDI 및 마이크로비아 기판은 유럽의 인쇄회로기판(PCB) 시장 점유율의 30.88%를 차지하며 자동차용 ECU 및 산업용 제어 장비를 위한 복잡한 상호연결 솔루션으로의 전환이 진행되고 있음을 보여주었습니다. OEM 제조업체가 기존의 관통구멍 설계에서 다층 마이크로비아 구조로 이행함에 따라 설치 면적의 축소와 신호 성능의 향상이 도모되기 때문에 HDI 용도의 유럽의 인쇄회로기판(PCB) 시장 규모는 꾸준히 확대를 계속하고 있습니다. 리지드 플렉스 기판은 수량적으로는 극히 일부에 불과하지만, 의료기기의 소형화나 자동차용 레이더 하네스에 있어서 리지드 영역간의 굴곡 가능한 접속 수요에 의해 2031년까지 연평균 복합 성장률(CAGR) 3.13%를 나타낼 전망입니다.

표준 다층 기판은 비용에 중점을 둔 산업용 모듈 분야에서 여전히 중요성을 유지하지만 가격 압력으로 범용품 생산은 아시아로 전환하고 있습니다. 플렉서블 회로는 생체 적합성과 멸균 대응이 요구되는 이식형·웨어러블 생체 센서용으로, 유럽의 제조 거점은 ISO 13485 인증을 강점으로 하고 있습니다. 리지드 1-2면 기판은 저이익률 생산으로부터의 철수에 의해 축소 경향에 있습니다. 전반적으로 유럽의 인쇄회로기판(PCB) 시장은 최저 비용보다 근접성, 전문성, 문서화에 중점을 둔 HDI 및 리지드 플렉스 수요로 탄력적입니다.

2025년 시점에서 유럽 인쇄회로기판(PCB) 시장 점유율의 26.12%를 차지한 자동차 분야는 2031년까지 연평균 복합 성장률(CAGR) 3.08%로 급성장하는 전기자동차 플랫폼에 지지되고 있습니다. 배터리 관리 시스템, 차량 충전기, ADAS 유닛이 보다 고층화되고 내열성 강화 기판을 채용함에 따라 유럽의 자동차 전자 기기용 인쇄회로기판(PCB) 시장 규모는 계속 확대되고 있습니다. 산업 자동화 및 인더스트리 4.0 이니셔티브는 스마트 팩토리 전체에 고밀도 센서가 장착된 컨트롤러 보드를 통합하여 중간 수준의 단일 자릿수 성장을 유지합니다.

통신 인프라 확장, 특히 5G 및 에지 데이터센터는 다층 기판 수요를 끌어올립니다. 한편, 항공우주 및 방위 분야는 엄격한 인증 사이클을 요하는 소규모이면서 고부가가치의 틈새 시장으로서 존속합니다. 의료 전자 기기는 생체 적합성 유연한 기판을 기반으로 하는 이식형 자극 장치나 진단용 웨어러블 기기를 배경으로 확대합니다. 유럽 제조업체가 높은 볼륨의 상품 휴대폰이나 태블릿에서 철수하고 규제 보증을 필요로 하는 전문 장비에 주력하는 가운데, 소비자용 전자 기기는 가장 약한 분야입니다.

Europe PCB market size in 2026 is estimated at USD 2.74 billion, growing from 2025 value of USD 2.67 billion with 2031 projections showing USD 3.14 billion, growing at 2.76% CAGR over 2026-2031.

This trajectory reflects a strategic pivot away from commoditized volumes toward regulated high-value niches in automotive, medical, and industrial automation that support premium pricing. The Europe PCB market benefits from the European Union's EUR 43 billion (USD 48.6 billion) Chips Act stimulus, which channels investment into semiconductor fabs, advanced packaging hubs, and supporting interconnect suppliers. Supply-chain security, regulatory conformity, and proximity to demanding OEMs continue to reinforce regional orders, even as production represents less than 2% of global output. Competitive stress from low-cost Asian imports persists, yet European companies mitigate margin pressure through HDI leadership, rigorous quality programs, and specialized design services. Consolidation further defines the Europe PCB market, as illustrated by SOMACIS's medical-grade acquisition and Cicor's record intake, signaling a flight to scale or specialization among remaining players.

The relentless push toward smaller, lighter electronic assemblies compels OEMs to specify HDI and ultra-HDI boards, elevating the Europe PCB market to a leadership role in microvia fabrication. Regional suppliers now qualify 50 micrometer conductor widths and microvias below 75 micrometers, enabling multilayer stack-ups that replace older through-hole designs with improved signal integrity. Investments in laser-drilling platforms, modified semi-additive processes, and X-ray inspection underpin these capabilities, with NCAB Group and Austrian specialists accelerating factory-readiness programs throughout 2025. The Europe PCB market thereby gains resilience through technical differentiation that deters price-based competition. In addition, stringent automotive and medical standards reward producers that document process control and traceability, reinforcing value extraction from HDI production. As adoption scales from German automotive clusters to Dutch industrial IoT hubs, HDI demand sustains a mid-term lift on regional revenue growth

Tighter 2025 European CO2 thresholds ignited a 21% year-over-year spike in battery-electric vehicle registrations to more than 250,000 units in January alone, translating to a sharp uptick in complex multilayer board content per vehicle. Battery-management systems, traction inverters, and ADAS modules now rely on eight-plus-layer HDI designs with stringent vibration and thermal cycling prescriptions certified under IPC-6012 automotive addenda. Consequently, the Europe PCB market secures recurring orders from tier-one suppliers that mandate regional production for just-in-time assembly near German, French, and Italian EV plants. The electric-vehicle subsegment posts the fastest CAGR within automotive, ensuring a durable volume driver through 2030. Suppliers leverage long qualification cycles and punitive defect penalties to defend margins against imports, while collaborating with OEMs to co-optimize board layout and power-density within constrained pack footprints.

Copper traded above USD 11,000 per metric ton in May 2024 before retreating below USD 9,000 later that year, and research anticipates a rebound past USD 10,000 by late 2025 on electrification demand. Because copper forms 40% of raw-material spend and materials consume about 40% of total cost, swings directly compress EBITDA for European fabs already grappling with elevated labor and energy overheads. Laminate suppliers likewise pushed double-digit surcharges during the 2024 squeeze, compelling many board houses to renegotiate annual pricing or pass through quarterly adjustment clauses. The Europe PCB market therefore confronts margin volatility that disproportionately hurts smaller firms lacking hedging programs or long-term supply contracts. Some mitigate exposure by specializing in HDI prototypes where material share of selling price is lower, while others adopt dynamic quoting software that recalculates copper and laminate indices in real time.

Other drivers and restraints analyzed in the detailed report include:

For complete list of drivers and restraints, kindly check the Table Of Contents.

HDI and micro-via boards accounted for 30.88% of the Europe PCB market share in 2025, underscoring the region's pivot to complex interconnect solutions for automotive ECUs and industrial controls. The Europe PCB market size for HDI applications continues to expand steadily as OEMs convert legacy through-hole designs to multilayer micro-via architectures that shrink footprint and enhance signal performance. Rigid-Flex formats, while only a fraction of volume, achieve a 3.13% CAGR to 2031 as medical device miniaturization and automotive radar harness bendable linkages between rigid zones.

Standard multilayer boards retain relevance in cost-sensitive industrial modules, though price pressure pushes commodity production toward Asia. Flexible circuits serve implantables and wearable biosensors that demand biocompatibility and sterilization compliance, domains where European fabs leverage ISO 13485 accreditation. Rigid 1-2-sided boards erode as producers exit low-margin runs. Overall, the Europe PCB market derives resilience from HDI and Rigid-Flex demand that values proximity, expertise, and documentation over lowest cost.

Automotive accounted for 26.12% of the Europe PCB market share in 2025, buoyed by surging electric-vehicle platforms that register a 3.08% CAGR through 2031. The Europe PCB market size for automotive electronics grows as battery-management systems, on-board chargers, and ADAS units integrate higher layer counts and thermal-enhanced substrates. Industrial automation and Industry 4.0 initiatives sustain mid-single-digit growth by embedding sensor-dense controller boards across smart factories.

Communications build-out, notably 5G and edge-data centers, uplifts multilayer demand, whereas aerospace and defense persist as small yet premium niches with rigorous qualification cycles. Medical electronics expand on the back of implantable stimulators and diagnostic wearables that rely on biocompatible flex boards. Consumer electronics remains the weakest cohort as European players relinquish high-volume commodity handsets and tablets, instead concentrating on specialized equipment demanding regulatory assurance.

The Europe PCB Market Report is Segmented by Category (Standard Multilayer PCBs, Rigid 1-2-Sided PCBs, and More), End-User Vertical (Industrial Electronics, Consumer Electronics, and More), PCB Substrate (FR-4, Metal Core, Polyimide, and More), Layer Count (1-2 Layers, 4-6 Layers, 8-10 Layers, and More), Assembly Type (Surface-Mount Technology, and More), and Geography. The Market Forecasts are Provided in Terms of Value (USD).