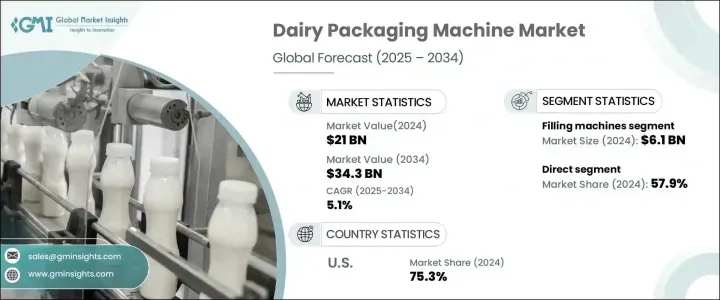

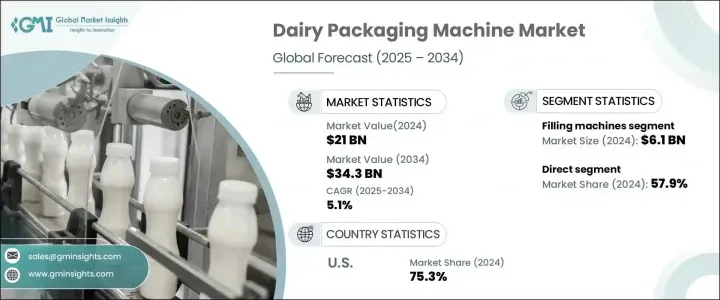

세계 유제품 포장기 시장은 2024년 210억 달러로 평가되었으며, 2025년부터 2034년까지 연평균 복합 성장률(CAGR) 5.1%로 성장할 것으로 예측됩니다.

세계 인구 증가와 가처분 소득 증가가 함께 세계 유제품 소비가 급증하고 있습니다. 우유, 치즈, 요구르트, 버터 등의 제품은 특히 도시화와 식생활의 기호 변화가 시장 확대의 원동력이 되고 있는 신흥국에서 수요가 높아지고 있습니다. 또한 소비자는 식품의 편의성, 안전성 및 보존 기간을 점점 더 우선시하고 있으며, 유제품 제조업체는 고급 패키징 솔루션에 대한 투자를 강요하고 있습니다.

포장기는 제품 무결성을 유지하고 폐기물을 줄이고 생산 공정을 간소화하는 데 매우 중요한 역할을 합니다. 이러한 발전은 소비자의 기대에 부응할 뿐만 아니라 제조업체들이 엄격한 규제 기준을 준수하는 데 도움이 되고 시장에 큰 성장 기회를 창출하고 있습니다. 유제품 포장기의 자동화, IoT 및 지속가능성에 중점을 둔 기술의 통합은 비즈니스 효율성을 더욱 높이고 환경 문제를 해결하며 시장을 지속적인 성장에 자리잡고 있습니다.

| 시장 범위 | |

|---|---|

| 시작 연도 | 2024년 |

| 예측 연도 | 2025-2034년 |

| 시작 금액 | 210억 달러 |

| 예측 금액 | 343억 달러 |

| CAGR | 5.1% |

시장은 유형별로 Form Fill Seal(FFS) 기계, 팔레타이징 기계, 카토닝 기계, 충전 기계, 포장 기계, 라벨링 기계 등으로 구분됩니다. 이 중 충전 기계는 2024년 61억 달러에 이르렀고, 가장 높은 수익원으로 떠올랐으며, 예측 기간 동안 CAGR은 5.6%를 나타낼 전망입니다. 충전 기계는 액체 우유, 크림, 버터, 분말 우유를 포함한 다양한 유제품 포장에 필수적입니다. 다양한 제품의 점도나 포장 형태에 대응할 수 있기 때문에 소비자 수요 증가를 목표로 하는 유제품 제조업체에 있어서 중요한 자산이 되고 있습니다.

유통 채널별로 시장은 직접 부문와 간접 부문으로 나뉩니다. 직접 판매 부문은 2024년 시장 점유율의 57.9%를 차지했으며 예측 기간 동안 CAGR은 5.2%를 나타낼 전망입니다. 직접 판매는 맞춤형 솔루션을 제공하고 제조업체와 구매자 간의 원활한 커뮤니케이션을 촉진하는 효율성으로 시장을 독점합니다. 이 채널을 통해 유제품 제조업체는 특정 업무 요구 및 규제 요구 사항에 따라 맞춤 설계된 기계를 얻을 수 있으며 업계에 엄청난 가치를 제공할 수 있습니다.

미국의 유제품 포장기 시장은 2024년에 75.3%의 점유율로 세계 시장을 석권했고 예측 기간 동안 4.9%의 연평균 복합 성장률(CAGR)로 성장할 것으로 예상됩니다. 이 나라의 첨단 낙농 부문은 혁신적인 패키징 기술의 채택을 촉진하는 견고한 공급망과 대규모 생산 시설의 혜택을 누리고 있습니다. 최첨단 유제품 가공 및 포장 장비에 대한 많은 투자는 미국 시장의 리더십을 더욱 견고하게 만들고 유제품 생산의 혁신과 효율성에 대한 헌신을 강조합니다.

The Global Dairy Packaging Machine Market was valued at USD 21 billion in 2024 and is projected to grow at a CAGR of 5.1% from 2025 to 2034. The rising global population, coupled with increasing disposable incomes, is fueling a surge in dairy consumption worldwide. Products like milk, cheese, yogurt, and butter are witnessing heightened demand, especially in emerging economies where urbanization and changing dietary preferences are driving market expansion. Additionally, consumers are increasingly prioritizing convenience, safety, and longer shelf life in food products, compelling dairy producers to invest in advanced packaging solutions.

Packaging machines are playing a pivotal role in maintaining product integrity, reducing waste, and streamlining production processes. These advancements not only meet consumer expectations but also help manufacturers comply with stringent regulatory standards, creating significant growth opportunities in the market. The integration of automation, IoT, and sustainability-focused technologies in dairy packaging machinery is further elevating operational efficiency and addressing environmental concerns, positioning the market for sustained growth.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $21 Billion |

| Forecast Value | $34.3 Billion |

| CAGR | 5.1% |

The market is segmented by type into form-fill-seal (FFS) machines, palletizing machines, cartoning machines, filling machines, wrapping machines, labeling machines, and others. Among these, filling machines emerged as the highest revenue generator in 2024, reaching USD 6.1 billion, and are anticipated to grow at a CAGR of 5.6% during the forecast period. Filling machines are indispensable for packaging a variety of dairy products, including liquid milk, cream, butter, and powdered milk. Their ability to handle diverse product viscosities and packaging formats makes them a critical asset for dairy manufacturers aiming to meet the growing consumer demand.

By distribution channel, the market is divided into direct and indirect segments. The direct segment accounted for 57.9% of the market share in 2024 and is projected to grow at a CAGR of 5.2% during the forecast period. Direct sales dominate the market due to their efficiency in offering tailored solutions and facilitating seamless communication between manufacturers and buyers. This channel enables dairy producers to acquire custom-designed machinery that aligns with specific operational needs and regulatory requirements, delivering immense value to the industry.

The US dairy packaging machine market dominated the global landscape with a 75.3% share in 2024 and is expected to grow at a CAGR of 4.9% during the forecast period. The country's advanced dairy sector benefits from a robust supply chain and large-scale production facilities that promote the adoption of innovative packaging technologies. Significant investments in cutting-edge dairy processing and packaging equipment further solidify the US market's leadership and underscore its commitment to innovation and efficiency in dairy production.