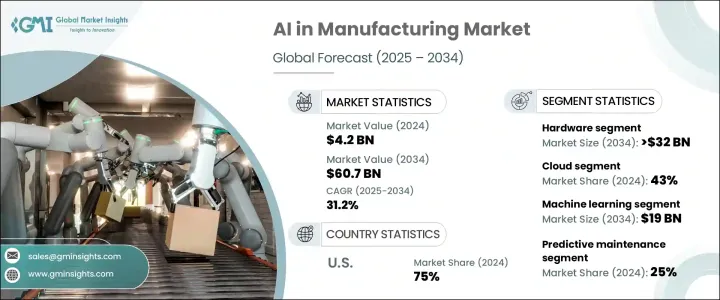

세계 제조업 AI 시장은 2024년에 42억 달러로 평가되었으며, 2025년부터 2034년에 걸쳐 31.2%의 연평균 복합 성장률(CAGR)로 성장할 것으로 예측되고 있습니다.

제조업에서 합리화된 아웃소싱 솔루션에 대한 요구가 증가함에 따라 AI의 채택을 촉진하고 있습니다. 기업은 생산 관리, 검사, 재고 관리 등의 프로세스를 자동화하여 생산 효율을 높이고 비용을 절감하며 사업을 확대하기 위해 AI를 통합하고 있습니다. AI를 활용한 솔루션의 가용성 증가는 선도적인 제조 업체에서 중소기업에 이르기까지 모든 규모의 기업에게 혜택을 줍니다. 세계 각국의 정부는 AI의 연구개발을 우선시하고 있으며, AI의 도입을 촉진하기 위한 자금 제공 프로그램, 세제 우대 조치, 규제 지원 등의 재정적 인센티브를 제공합니다. 이러한 이니셔티브는 다양한 산업에서 혁신을 촉진하고 생산성을 높이고 비용을 절감하는 것을 목표로 합니다.

시장은 구성 요소에 따라 하드웨어, 소프트웨어, 서비스로 구분됩니다. 2024년에는 하드웨어 분야 시장 점유율이 55%를 초과하고 2034년에는 320억 달러 이상에 달할 것으로 예상됩니다. 로봇공학, 예지보전, 품질관리 등 제조업 AI 용도는 실시간 데이터 처리에 고성능 컴포넌트를 필요로 하기 때문에 고도의 컴퓨팅 하드웨어에 대한 수요 증가가 이 성장을 뒷받침하고 있습니다. 머신러닝 및 딥러닝 알고리즘은 AI 성능을 향상시키는 강력한 하드웨어의 필요성을 높입니다. 데이터 처리 능력의 급속한 진보로 자동화 확대, 생산성 향상, 의사결정 개선이 가능해지고 있습니다.

| 시장 범위 | |

|---|---|

| 시작 연도 | 2024년 |

| 예측 연도 | 2025-2034년 |

| 시작 금액 | 42억 달러 |

| 예측 금액 | 607억 달러 |

| CAGR | 31.2% |

배포 모델별로 온프레미스 솔루션과 클라우드 솔루션으로 분류됩니다. 2024년에는 클라우드 부문이 시장의 약 43%를 차지했습니다. 각 업계의 기업이 디지털 전환을 도입하면서 클라우드 기반 AI 솔루션에 대한 수요가 높아지고 제조업의 경쟁력이 강화되고 있습니다. 클라우드 컴퓨팅은 유연성과 확장성을 제공하여 운영 비용을 줄이고 프로세스를 간소화합니다. 또한 원격지에 도입하여 데이터의 저장과 처리를 강화할 수 있기 때문에 방대한 데이터 세트에 의존하는 AI 용도에 필수적입니다. 또한 클라우드 기반 솔루션은 제조업체, 공급업체, 고객 간의 실시간 협업을 가능하게 하고 의사결정을 개선하며 시장 출시 시간을 단축합니다.

시장은 머신러닝, 컴퓨터 비전, 자연 언어 처리, 컨텍스트 대응 컴퓨팅 등 기술별로 구분됩니다. 머신러닝은 시장을 선도하고 2034년까지 약 190억 달러를 창출할 것으로 예상됩니다. 이러한 성장은 지능적인 자동화와 데이터 중심의 의사결정을 위한 머신러닝의 사용 증가로 인한 것입니다. AI 주도 품질 관리 솔루션은 제품 검사의 정확성을 향상시키고 생산 손실을 최소화합니다. 제조업에서의 머신러닝의 채용은 최적화된 운영을 위해 데이터를 수집, 분석 및 처리하는 IoT 기술의 시작으로도 추진되고 있습니다.

이 시장은 또한 품질 관리, 예지 보전, 재고 관리, 에너지 관리, 산업용 로봇 등을 포함한 용도별로 분류됩니다. 예지보전은 2024년에 약 25%의 최대 점유율을 차지했습니다. AI를 활용한 예지보전 솔루션은 머신러닝 알고리즘을 사용하여 장비의 성능을 실시간으로 모니터링 및 평가하여 고장 방지, 보전 비용 절감, 생산 중단 최소화를 지원합니다. 생산성 향상과 가동 중지 시간 절감에 대한 요구가 증가함에 따라 이러한 시스템에 대한 수요가 증가하고 있습니다.

미국은 2024년 북미 제조업에서 AI 시장을 선도하여 지역 점유율의 약 75%를 차지했습니다. AI 주도의 스마트 제조에 대한 이 나라의 강력한 정부 지원이 시장 성장의 주요 요인이 되고 있습니다. 정책 입안자는 국내 제조업의 경쟁력을 강화하기 위해 자동화와 첨단 기술을 우선하고 있습니다. 또한 공급망의 강인성 강화와 생산 효율 최적화에 중점을 두는 것은 업계에서 AI의 채용을 더욱 촉진하고 있습니다.

The Global AI In Manufacturing Market was valued at USD 4.2 billion in 2024 and is projected to grow at a CAGR of 31.2% between 2025 and 2034. The increasing need for streamlined outsourcing solutions within the manufacturing sector is driving AI adoption. Companies are integrating AI to enhance production efficiency, cut costs, and scale operations by automating processes such as production control, inspection, and inventory management. The rising availability of AI-powered solutions is benefiting businesses of all sizes, from large manufacturers to small and medium enterprises. Governments worldwide are prioritizing AI research and development, offering financial incentives such as funding programs, tax breaks, and regulatory support to boost AI implementation. These initiatives are designed to drive innovation, improve productivity, and reduce costs across various industries.

The market is segmented based on components into hardware, software, and services. In 2024, the hardware segment held a market share exceeding 55% and is expected to surpass USD 32 billion by 2034. The rising demand for advanced computing hardware is fueling this growth, as AI applications in manufacturing, such as robotics, predictive maintenance, and quality control, require high-performance components for real-time data processing. Machine learning and deep learning algorithms are also driving the need for powerful hardware to improve AI performance. Rapid advancements in data processing capabilities are enabling greater automation, enhanced productivity, and better decision-making.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $4.2 Billion |

| Forecast Value | $60.7 Billion |

| CAGR | 31.2% |

By deployment model, the market is categorized into on-premises and cloud solutions. In 2024, the cloud segment accounted for about 43% of the market. As companies across industries embrace digital transformation, the demand for cloud-based AI solutions is rising, enhancing competitiveness in manufacturing. Cloud computing offers flexibility and scalability, reducing operational costs and streamlining processes. Additionally, remote implementation allows for enhanced data storage and processing, which is critical for AI applications that rely on extensive datasets. Cloud-based solutions also enable real-time collaboration between manufacturers, suppliers, and customers, improving decision-making and accelerating time to market.

The market is also segmented by technology, including machine learning, computer vision, natural language processing, and context-aware computing. Machine learning led the market and is projected to generate around USD 19 billion by 2034. This growth is attributed to the increasing use of machine learning for intelligent automation and data-driven decision-making. AI-driven quality control solutions improve product inspection accuracy, minimizing production losses. Machine learning adoption in manufacturing is also being propelled by the rise of IoT technologies, which collect, analyze, and process data for optimized operations.

The market is further divided by application, including quality management, predictive maintenance, inventory management, energy management, industrial robotics, and others. Predictive maintenance held the largest share in 2024 at approximately 25%. AI-powered predictive maintenance solutions use machine learning algorithms to monitor and assess equipment performance in real-time, helping businesses prevent failures, reduce maintenance costs, and minimize production disruptions. The increasing need for higher productivity and reduced downtime is driving demand for these systems.

The United States led the North America AI in manufacturing market in 2024, holding about 75% of the regional share. The country's strong government support for AI-driven smart manufacturing is a key factor in market growth. Policymakers are prioritizing automation and advanced technologies to enhance the competitiveness of the nation's manufacturing sector. In addition, a focus on strengthening supply chain resilience and optimizing production efficiency is further driving AI adoption in the industry.