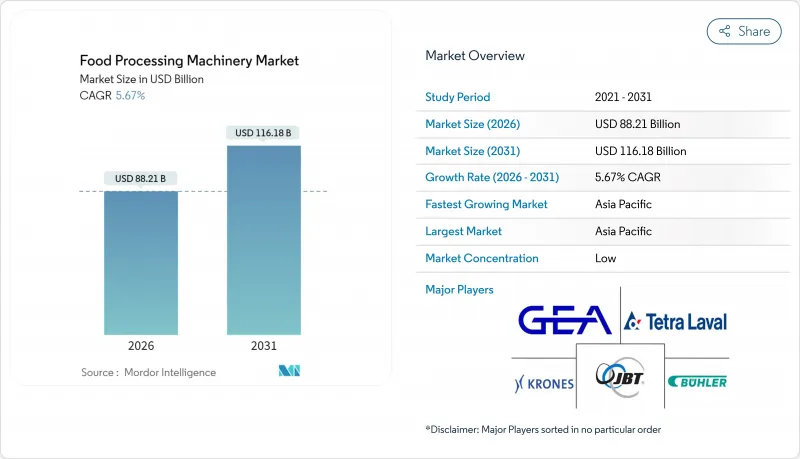

2026년 식품 가공 기계 시장 규모는 882억 1,000만 달러로 추정되며, 2025년 834억 8,000만 달러부터 성장을 거두었으며, 2031년에는 1,161억 8,000만 달러에 달할 것으로 예측됩니다.

2026년부터 2031년까지의 연평균 성장률(CAGR)은 5.67%를 나타낼 전망입니다.

공장 바닥의 꾸준한 현대화, 위생 규제의 엄격화, 포장 식품의 소비 증가가 이 성장 궤도를 지원합니다. 가공 기계는 계속해서 가장 큰 수익 점유율을 차지하고 있으며, 이는 제조업체가 1차 가공 설비를 생산성 향상과 안정적인 제품 품질에 대한 가장 확실한 수단으로 간주하고 있기 때문입니다. 아시아태평양의 산업 확대와 확대하는 중산계급의 구매력이 결합되어 진화하는 식품안전규제에 준거한 선진시스템에 대한 지역 수요를 가속화하고 있습니다. 자동화는 여전히 중요하며, 현재의 설치 설비에서는 반자동 라인이 주류이지만, 기업이 예지 보전, 자원 효율화, 실시간 품질 감시를 추구하는 가운데, 스마트 기기나 AI 탑재 기기의 도입이 가장 급속히 진행되고 있습니다. 공급 기반이 분산되어 있기 때문에 경쟁의 치열성은 중간 정도로 유지되고 있으며, 혁신 기업은 전문적이고 연결성이 높은 솔루션으로 점유율을 얻고 있습니다.

소비자의 라이프 스타일이 편리성을 중시한 소비 패턴으로 이행하는 중, 가공·포장 분야 전체에서 지속적인 설비 투자가 촉진되고 있습니다. 미국의 레이디밀 시장은 633억 달러 규모에 이르고, CAGR 9.1%로 확대되고 있으며, 다양한 제품 처방과 포장 형태에 대응 가능한 유연한 가공 라인에 대한 업스트림 수요를 창출하고 있습니다. 이러한 추세는 대규모 재구성 없이 신속한 제품 전환을 가능하게 하는 모듈식 시스템을 제공하는 제조업체에게 특히 유리합니다. 고스트 주방 사업자는 공간 이용률을 극대화하면서 다중 컨셉 조리를 가능하게 하는 콤팩트하고 배기 불필요한 설비 솔루션의 채용이 증가하고 있습니다. 알트 샴사의 벡터 H시리즈 멀티쿡 오븐이 가상 셰프홀의 7개 컨셉 운영을 뒷받침하는 사례가 이를 보여줍니다. 딜리버리 중심의 비즈니스 모델과 첨단 가공 기술의 융합은 도시 지역의 공동 조리장 운영을 목표로 하는 설비 공급업체에게 새로운 시장 부문을 창출하고 있습니다.

제조 인텔리전스 플랫폼은 식품 가공을 반응적인 유지보수에서 예측형 운영 모델로 전환하여 설비 가동률과 제품 품질을 최적화합니다. 로크웰 오토메이션의 FactoryTalk Analytics 플랫폼은 가공 파라미터의 실시간 모니터링을 가능하게 하고, 계획외 정지 시간을 최대 30% 단축하는 동시에 종합 설비 효율(OEE)을 향상시킵니다. 이 기술적 변혁은 작은 효율성 향상이 상당한 비용 절감으로 이어지는 대량 가공 환경에 특히 영향을 미칩니다. 스마트 가공 장비에는 엣지 컴퓨팅 기능이 내장되어 있는 케이스가 증가하고 있어, 클라우드 접속에 의존하지 않고 로컬에서의 의사 결정을 가능하게 함으로써, 시간적 제약이 있는 작업에 있어서 지연 문제를 해결합니다. 셰프로보틱스의 AI 탑재 디스포팅 시스템이 균일성과 수율을 30% 이상 개선한 사례로 대표되는 바와 같이, 식품 가공 기계에 대한 인공지능 통합은 머신러닝 알고리즘이 분량 관리를 최적화하고 식품 폐기를 줄이는 방법을 입증하고 있습니다.

첨단 가공 설비에 대한 투자 장벽은 대규모 제조업체와 비용 효율적인 자동화 솔루션을 요구하는 중소기업과 시장 세분화를 낳고 있습니다. 316L 스테인레스 스틸 구조와 특수 표면 처리를 포함한 고급 위생 설계 요구 사항은 표준 산업기계와 비교하여 장비 비용을 크게 증가시킵니다. GEA가 도입한 엔트리 레벨 열성형기는 하이엔드 시스템에 자본 투자 없이 고도의 포장 기능을 요구하는 중소기업을 대상으로 하고 있습니다. 특수 세척제, 밸리데이션 절차 및 유지보수 프로토콜에는 지속적인 자금이 필요하므로 운영 비용이 초기 투자의 과제를 더욱 복잡하게 합니다. 이 비용 구조는 자동화의 이점과 자본 제약의 균형을 맞추어야 하는 신흥 시장 제조업체에 특히 영향을 미치고 유연한 자금 조달 및 임대 모델을 제공하는 설비 공급업체에게 기회를 창출하고 있습니다.

식품 가공 기계 시장에서 2025년 수익의 53.92%를 가공설비가 차지해 제조업체가 핵심가치 창출에 주력하고 있음을 반영했습니다. 열처리, 비열처리, 압출기술이 생산능력 확대의 기반을 형성하여 5.04%의 연평균 복합 성장률(CAGR) 전망을 기록했습니다. 뷰러의 SmartLine 릴리즈(인도에서 생산되는 DirectBake Smart 오븐 포함)는 하이엔드 연소 제어 및 레시피 관리를 현지 가격대에 맞추어 조정합니다. 포장 기계는 매출에서 2위인 채로 충전 속도·씰 온도·라벨 공급을 동기화하는 통합 제어에 의해 업스트림 공정과의 제휴를 강화하고 있습니다. CIP 스키드, 폐기물 처리 유닛, HVAC 시스템 등의 유틸리티는 물·에너지·화학약품 소비량을 분석하는 공장 전체의 대시보드에 연동. 이 협력은 식품 가공 기계 시장이 기계 수준의 성능에서 전체 라인 최적화로 전환하고 있음을 보여줍니다.

D2C 브랜드와 신속한 전환을 중시하는 고스트 키친이 증가하는 가운데, 유연한 소 로트 대응의 열처리 시스템에 대한 수요가 높아지고 있습니다. 한편, 대규모 플랜트에서는 수출용 채널에 대응하기 위해, 고처리 능력의 증발기, UHT 장치, 무균 충전기가 도입되고 있습니다. 열교환기, 펌프, 밸브 매니폴드를 모듈화한 공급업체는 가공업자가 여러 예산 사이클에 걸쳐 투자를 단계적으로 진행할 수 있게 하고, 현금 흐름이 변동하더라도 도입 계획을 유지할 수 있도록 하고 있습니다. 사이버 보안 대책을 실시한 PLC나 산업용 이더넷이 표준화되는 가운데, 설비간의 상호 운용성은 더 이상 사치품이 아니고, 경쟁상의 필수 요건이 되고 있습니다.

식품 가공 기계 시장은 기계 유형(가공 기계 등), 자동화 수준(수동, 반자동, 전자동, 스마트 및 AI 대응), 용도(베이커리, 과자 등), 지역(북미, 유럽, 아시아태평양, 남미, 중동, 아프리카)에 의해 세분화됩니다. 예측은 금액 기준(달러)으로 제공됩니다.

2025년 아시아태평양은 세계 수익의 38.21%를 차지했으며 CAGR 5.33%를 나타낼 전망입니다. 이는 이 지역이 세계 생산능력 확대에 있어서 매우 중요한 역할을 담당하고 있음을 보여줍니다. 식품 수출의 급증, 도시에서의 소비 확대, 국내 가공의 근대화를 위한 정부의 우대 조치 등의 요인이 이 지역의 성장을 지지하고 있습니다. 인도네시아의 카길과 인도의 론자를 비롯한 다국적 대기업은 국내 시장과 인근 수출 회랑 모두에 대응하기 위해 현지 생산 확대를 추진하고 있습니다. 이 지역의 조달 부문은 짧은 배달 시간, 현지 조달 가능한 예비 부품 및 신속한 판매 후 서비스를 제공하는 기계 공급업체를 점점 더 중요하게 생각합니다. 이 동향은 지역 특유의 작물·축산 프로파일에 맞춘 모듈식 시스템, 자동 검사 기술, 연속 가공 라인에 대한 수요를 촉진하고 있습니다.

북미에서는 신규 건설에 의한 확장보다 기존 인프라의 최적화에 주력하고 있습니다. 가공업자는 디지털 리노베이션, 예지 보전 시스템 및 에너지 절약에 대한 투자를 추진하고 있습니다. 철강·알루미늄에 대한 관세 인상으로 설비 제조 비용이 25% 급등함에 따라 구매자는 지역 OEM 업체와 미국에 조립 거점을 두는 세계 기업으로의 전환을 촉구하고 있습니다. 시장에서는 분량조정, 포장, 위생관리 등의 작업에 있어서 로봇 도입이 급속히 진행되고 있습니다. 이러한 변화는 주로 노동력 부족, 엄격한 위생 기준, 다양한 제품 SKU의 생산 변동 관리 과제에 의해 추진되고 있습니다.

남미, 중동, 아프리카에서는 식품 가공 기반의 정비를 향한 협조적인 대처가 진행되고 있습니다. 이 이니셔티브는 식량 안보 강화, 수확 후 손실 감소, 농촌 지역의 농업 산업 밸류체인 활성화를 목표로 합니다. 이동식 과실 가공 유닛, 컨테이너형 유제품 라인, 태양광 발전식 탈수기, 저압식 가금류 통기기 등의 혁신 기술이 도입되고 있습니다. 이러한 기술은 콜드체인에 대한 액세스가 제한되고 전력 공급이 불안정한 지역에서 특히 유용합니다. 정부 지원의 근대화 조성금이나 관민 연계에 의해 중소 가공업자의 설비 갱신이 진행되는 한편, 환율 변동이나 수입 의존 등의 과제에 의해 기계 발주가 지연되는 사례도 볼 수 있습니다. 그러나 이 지역의 종합적인 목표는 명확합니다. 중요한 생산 능력의 격차를 메우고 현지 부가가치를 높이고 확대하는 국내 수요에 공급을 적응시키는 것입니다.

Food processing machinery market size in 2026 is estimated at USD 88.21 billion, growing from 2025 value of USD 83.48 billion with 2031 projections showing USD 116.18 billion, growing at 5.67% CAGR over 2026-2031.

Steady modernization of plant floors, stricter hygiene regulations, and rising consumption of packaged foods underpin this growth trajectory. Processing machinery continues to command the largest revenue share because manufacturers view primary transformation equipment as the surest route to throughput gains and consistent product quality. Asia-Pacific's industrial build-out, coupled with expanding middle-class purchasing power, accelerates regional demand for advanced systems that comply with evolving food-safety mandates. Automation remains pivotal; semi-automatic lines dominate current installations, yet smart and AI-enabled equipment records the fastest uptake as firms pursue predictive maintenance, resource efficiency, and real-time quality monitoring. Competitive intensity stays moderate in a fragmented supplier base, enabling technology disruptors to win share with specialized, connected solutions.

Consumer lifestyle shifts toward convenience-oriented consumption patterns drive sustained equipment investment across processing and packaging segments. The U.S. ready meals market reached USD 63.3 billion with a 9.1% CAGR growth, creating upstream demand for flexible processing lines capable of handling diverse product formulations and packaging formats. This trend particularly benefits manufacturers offering modular systems that accommodate rapid product changeovers without extensive reconfiguration. Ghost kitchen operators increasingly specify compact, ventless equipment solutions that maximize space utilization while enabling multi-concept food preparation, as demonstrated by Alto-Shaam's Vector H Series Multi-Cook Oven powering Virtual Chef Hall's seven-concept operations. The convergence of delivery-focused business models with advanced processing technology creates new market segments for equipment suppliers targeting urban commissary operations.

Manufacturing intelligence platforms transform food processing from reactive maintenance toward predictive operational models that optimize equipment utilization and product quality. Rockwell Automation's FactoryTalk Analytics platform enables real-time monitoring of processing parameters, reducing unplanned downtime by up to 30% while improving overall equipment effectiveness. This technological shift particularly impacts high-volume processing environments where marginal efficiency gains translate to significant cost savings. Smart processing equipment increasingly incorporates edge computing capabilities that enable local decision-making without relying on cloud connectivity, addressing latency concerns in time-sensitive operations. The integration of artificial intelligence in food processing machinery, exemplified by Chef Robotics' AI-enabled depositing systems achieving greater than 30% improvement in consistency and yield, demonstrates how machine learning algorithms optimize portion control and reduce food waste.

Investment barriers for sophisticated processing equipment create market segmentation between large-scale manufacturers and smaller operators seeking cost-effective automation solutions. Advanced hygienic design requirements, including 316L stainless steel construction and specialized surface finishes, significantly increase equipment costs compared to standard industrial machinery. GEA's introduction of entry-level thermoforming machines specifically targets small and medium-sized companies seeking advanced packaging capabilities without the capital commitment of high-end systems. Operating expenses compound initial investment challenges, as specialized cleaning chemicals, validation procedures, and maintenance protocols require ongoing financial commitments. This cost structure particularly impacts emerging market manufacturers who must balance automation benefits against capital constraints, creating opportunities for equipment suppliers offering flexible financing and leasing models.

Other drivers and restraints analyzed in the detailed report include:

For complete list of drivers and restraints, kindly check the Table Of Contents.

Processing equipment captured 53.92% of 2025 revenue within the food processing machinery market, reflecting manufacturers' focus on core value generation. Thermal, non-thermal, and extrusion technologies form the backbone of capacity expansions and recorded a 5.04% CAGR outlook. Buhler's SmartLine release, including the DirectBake Smart oven produced in India, tailors high-end combustion and recipe controls to local price points. Packaging machinery ranks second in revenue yet increasingly integrates with upstream processes through unified controls that synchronize fill rates, sealing temperatures, and label feeds. Utilities such as CIP skids, waste-handling units, and HVAC systems tie into overarching plant-wide dashboards that analyze water, energy, and chemical consumption. This linkage illustrates how the food processing machinery market is moving from machine-level performance to holistic line optimization.

Demand for flexible, small-batch thermal systems rises alongside D2C brands and ghost kitchens that prioritize rapid changeovers. At the other end of the scale, mega-plants order high-throughput evaporators, UHT units, and aseptic fillers to serve export channels. Suppliers that modularize heat exchangers, pumps, and valve manifolds allow processors to phase investments over multiple budget cycles, keeping adoption on track even when cash flows fluctuate. As cyber-secure PLCs and industrial Ethernet become standard, equipment interoperability becomes a competitive requirement rather than a luxury.

The Food Processing Machinery Market is Segmented by Machinery Type (Processing Machinery and More), Automation Level (Manual, Semi-Automatic, Fully Automatic, Smart and AI-Enabled), Application (Bakery and Confectionery, and More), and Geography (North America, Europe, Asia-Pacific, South America, Middle East, and Africa). Forecasts are Provided in Value Terms (USD).

In 2025, the Asia-Pacific region is projected to contribute 38.21% to global revenue and is set to grow at a CAGR of 5.33%. This underscores the region's pivotal role in global capacity expansion. Factors such as surging food exports, urban consumption, and government incentives for modernizing domestic processing bolster the region's growth. Multinational giants, including Cargill in Indonesia and Lonza in India, are broadening their localized manufacturing to cater to both domestic markets and nearby export corridors. Procurement teams in the region are increasingly favoring machinery suppliers who offer shorter lead times, local spare parts, and swift after-sales service. This trend fuels demand for modular systems, automated inspection technologies, and continuous processing lines, all tailored to the region's unique crop and livestock profiles.

North America is focusing on optimizing its existing infrastructure instead of pursuing greenfield expansions. Processors are channeling investments into digital retrofits, predictive maintenance systems, and energy-efficient upgrades. Rising tariffs on steel and aluminium, leading to a 25% spike in equipment fabrication costs-are nudging buyers to turn to regional OEMs or global firms with U.S.-based assembly units. The market is witnessing a robust adoption of robotics for tasks like portioning, packaging, and sanitation. This shift is largely driven by labor shortages, stringent hygiene standards, and the challenge of managing production variability across diverse product SKUs.

In South America, the Middle East, and Africa, there's a concerted push to establish foundational food processing infrastructure. This initiative aims to bolster food security, curtail post-harvest losses, and invigorate rural agro-industrial value chains. Innovations like mobile fruit processing units, containerized dairy lines, solar-powered dehydrators, and low-pressure poultry scalders are being deployed. These technologies are especially beneficial in areas with limited cold-chain access and inconsistent grid connectivity. While government-backed modernization grants and public-private partnerships are aiding small and mid-sized processors in upgrading their equipment, challenges like foreign exchange volatility and a reliance on imports are causing delays in machinery orders. Nevertheless, the overarching goal in these regions remains clear: to bridge critical capacity gaps, enhance local value addition, and align supply with the growing domestic demand.