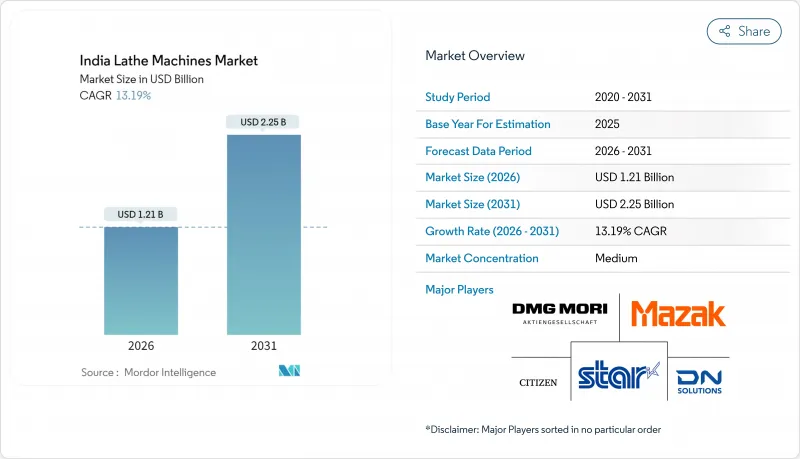

인도의 선반 시장은 2025년에 10억 7,000만 달러로 평가되었고, 2026년 12억 1,000만 달러에서 2031년까지 22억 5,000만 달러에 이를 것으로 예측됩니다. 예측기간(2026-2031년)의 CAGR은 13.19%를 나타낼 전망입니다.

이러한 성장 가속은 생산 연동 인센티브(PLI)의 배분, 전기자동차 제조의 급증, 중소 영세 기업(MSME)의 자동화의 보급에 의해 추진되고 있습니다. 항공우주, 방위, 의료기기 클러스터에서의 수요 증가로 최종 사용자 기반이 확대되고, 종래의 자동차 가공에 대한 의존도가 저하되고 있습니다. Industry 4.0 호환 개조 키트는 업그레이드 비용을 절감하고 2차 제조업체가 고급 기능을 사용할 수 있게 되면서 경쟁이 치열해지고 있습니다. 한편 국내외 주요기업은 고이익률 수주를 획득하기 위해 사물인터넷(IoT) 접속성, 예지보전, 다축정밀가공기능의 통합을 급피치로 진행하고 있습니다. 이러한 시너지 효과로 인도의 선반 시장은 2030년까지 지속적인 성장이 예상됩니다.

1조 9700억 루피 규모의 생산 연동형 인센티브(PLI) 프로그램은 공장 건설 시 정밀 CNC 선반 조달을 의무화하는 최저 투자 기준을 설정하고 있습니다. 푸네, 델리, 방갈로르 및 방갈로르의 CMTI(중앙기계기술연구소)에 설치된 스마트 첨단 제조 거점에서는 기술지도를 제공하여 단발적인 설비 구입이 아닌 지속적인 도입을 촉진하고 있습니다. PLI 하에서의 국내 조달 조건은 엄격한 부가가치 기준을 충족하는 인도 선반 기계 시장 솔루션의 현지 조달을 제조업체에게 더욱 추진하고 있습니다.

2024년 인도에서 조립된 전기차는 150만대에 달하고, 0.01mm 미만의 로터 동심도 요구가 타밀 나두주의 급성장하는 EV 회랑에서 스위스형 자동 선반의 도입을 가속화하고 있습니다. 2030년까지 70%의 현지화 목표가 달성되면 국내 가공량의 안정 공급이 보장되고 수입 대체가 제한됨에 따라 인도의 선반 시장은 더욱 확대될 전망입니다.

스위스형 모델은 500만루피에서 5,000만루피로 기존 유닛의 3-5배의 가격대이며 중소 영세기업의 예산을 압박하고 있습니다. 공구, 지그, CAM 소프트웨어가 취득 비용에 20-30% 상승하는 한편, CGTMSE에 의한 부분 보증에도 불구하고, 담보 중시의 은행 대출이 보급을 제한하고 있습니다.

인도의 선반 시장에서 CNC 플랫폼은 2025년 수익의 53.05%를 차지하고 수십년에 걸친 프로그램 가공의 보급을 뒷받침하고 있습니다. 전기자동차(EV), 항공우주, 의료기기 분야의 고객이 복잡한 다축 가공 능력을 요구하는 가운데 스위스형 자동 모델은 2031년까지 14.02%의 연평균 복합 성장률(CAGR)을 달성할 전망입니다. 인도의 선반 시장에서 스위스형 솔루션 시장 규모는 2031년까지 4억 7,000만 달러를 초과할 수 있지만, 레트로핏 키트가 가격차를 채우면 기존 유닛은 감소하는 경향이 있습니다. 일본 전산 머시닝 툴 등 세계 기업들은 이 정밀 가공 수요에 대응하기 위해 타밀 나두주에서 공구 공장 프로젝트를 확대 중입니다.

레트로 핏 패키지에 의한 설비 수명의 연장으로 기존과 CNC 기계의 성능 격차는 비용면에서 축소 경향이 있습니다. 그 결과, 소규모 가공 공장에서도 기존에는 대규모 OEM 공급업체가 독점하고 있던 고정밀 계약을 획득 가능하게 되어 인도의 선반 시장 전체에서 품질 기준 보급이 가속화되고 있습니다.

2025년 시점에서는 반자동 시스템이 매출액의 51.20%를 차지하고 있었습니다만, 자동장치는 CAGR14.08%로 성장을 지속하여, 2031년까지 38.20%의 점유율을 획득할 것으로 예측되고 있습니다. 숙련 노동자 부족과 엄격한 추적성 기준에 직면하는 기업이 늘어날수록 인도의 선반 시장에서의 자동 제어 점유율은 확대 경향이 있습니다. 원격 스핀들 모니터링 및 디지털 로그북은 의료 및 항공우주 분야에서 규제 준수를 지원하고 완전 자동화에 대한 투자 판단을 뒷받침합니다.

반면 수동 플랫폼은 훈련 센터와 소량 생산 공장에 여전히 존재하지만 디지털 리터러시가 향상됨에 따라 2031년까지 9.60% 미만으로 떨어질 것으로 예측됩니다. 반자동 기계에서 도입한 후 Industry 4.0 모듈을 추가하는 하이브리드 전략은 점진적인 변화를 요구하는 중소기업(MSME)에게 여전히 비용 효율적인 경로입니다.

The India Lathe Machines market was valued at USD 1.07 billion in 2025 and estimated to grow from USD 1.21 billion in 2026 to reach USD 2.25 billion by 2031, at a CAGR of 13.19% during the forecast period (2026-2031).

The acceleration is fueled by Production Linked Incentive (PLI) allocations, the electric-vehicle manufacturing surge, and widespread automation adoption among micro-, small-, and medium-enterprises (MSMEs). Growing demand from aerospace, defense, and medical-device clusters is broadening the end-user base and reducing historical reliance on automotive machining. Competition is intensifying as Industry 4.0 retrofit kits lower upgrade costs, enabling tier-2 manufacturers to access advanced capabilities. Meanwhile, global and domestic players are racing to embed Internet of Things (IoT) connectivity, predictive maintenance, and multi-axis precision to win high-margin orders. These converging forces promise sustained momentum for the India Lathe Machines market through 2030.

The INR 1.97 lakh-crore PLI program has set minimum investment thresholds that compel beneficiaries to procure precision CNC lathes during plant build-outs. Dedicated Smart Advanced Manufacturing hubs in Pune, Delhi, Bengaluru, and Bengaluru's CMTI offer technical guidance, ensuring sustained rather than one-off equipment purchases. Domestic content conditions under PLI further push manufacturers toward locally sourced India Lathe Machines market solutions that meet stringent value-addition norms.

India assembled 1.5 million electric vehicles in 2024, and rotor concentricity requirements below 0.01 mm have accelerated the adoption of Swiss-type automatic lathes in Tamil Nadu's rapidly growing EV corridor. Localization targets of 70% by 2030 guarantee steady domestic machining volumes and limit import substitution, further enlarging the India Lathe Machines market.

Swiss-type models priced at Rs 50 lakh-Rs 5 crore cost three to five times more than conventional units, stretching MSME budgets. Tooling, fixtures, and CAM software add 20-30% to acquisition cost, while collateral-heavy bank lending limits uptake despite partial guarantees under CGTMSE.

Other drivers and restraints analyzed in the detailed report include:

For complete list of drivers and restraints, kindly check the Table Of Contents.

CNC platforms captured 53.05% of 2025 revenue in the India Lathe Machines market, substantiating decades of programmable machining adoption. Swiss-type automatic models are on track for a 14.02% CAGR through 2031 as EV, aerospace, and medical-device customers demand complex multi-axis capability. The India Lathe Machines market size for Swiss-type solutions could surpass USD 0.47 billion by 2031, while conventional units decline as retrofit kits bridge affordability gaps. Global firms such as Nidec Machine Tool are ramping up tool-factory projects in Tamil Nadu to serve this precision demand.

The performance gap between conventional and CNC machines is narrowing in cost terms as retrofit packages extend equipment life cycles. As a result, small job shops can compete for high-tolerance contracts previously reserved for large OEM suppliers, accelerating diffusion of quality standards across the India Lathe Machines market.

Semi-automatic systems held 51.20% of revenue in 2025; however, automatic units are forecast to command 38.20% of value by 2031 on a 14.08% CAGR. The India Lathe Machines market share for automatic control jumps whenever firms face skilled-labor shortages or stringent traceability norms. Remote spindle monitoring and digital logbooks support regulatory compliance in medical and aerospace verticals, tipping investment decisions toward full automation.

Meanwhile, manual platforms still populate training centers and low-volume shops but are expected to fall below 9.60% by 2031 as digital literacy improves. The hybrid strategy of starting with semi-automatic machines then layering Industry 4.0 modules remains a cost-effective path for MSMEs seeking incremental change.

The India Lathe Machines Market Report is Segmented by Product Type (CNC Lathe, Conventional Lathe, and Swiss-Type Automatic Lathe), Control Type (Manual, Semi-Automatic, and Automatic), Operation (Turning, Facing, and More), End-User Industry (Automotive, Aerospace and Defence, and More), and Region. The Market Forecasts are Provided in Terms of Value (USD).