반도체 계측 및 검사는 반도체 디바이스의 품질, 신뢰성 및 성능을 보장하는 데 있어 매우 중요한 역할을 합니다. 이 분야의 발전과 투자는 몇 가지 원동력에 의해 추진되고 있습니다.

전체적으로, 반도체 산업의 끊임없는 혁신 추구와 성능 및 품질에 대한 기대치가 높아지면서 계측 및 검사 기술의 지속적인 발전이 이루어지고 있습니다. 이러한 도구는 현대 전자제품을 뒷받침하는 최첨단 반도체 디바이스의 개발 및 생산을 가능하게 하는 데 필수적입니다.

반도체 제조 공정이 복잡해짐에 따라 실시간 공정 제어의 필요성이 증가하고 있습니다. 첨단 계측 및 검사 시스템을 통해 제조업체는 공정을 면밀히 모니터링하고 최적의 성능과 처리량을 보장하기 위해 즉각적인 조정을 할 수 있습니다. 이러한 실시간 피드백 루프는 정밀 제조와 생산 효율성의 미묘한 균형을 유지하는 데 필수적입니다.

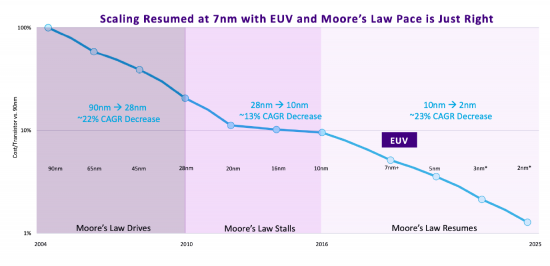

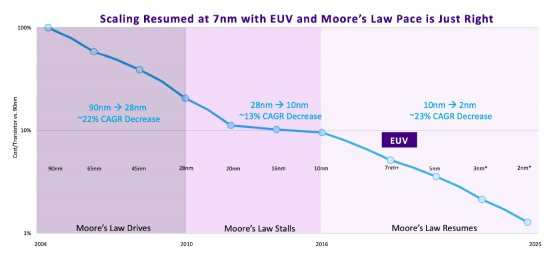

마이크로칩의 트랜지스터가 약 2년마다 두 배로 증가하고 동시에 비용이 감소하는 무어의 법칙의 추구는 반도체 소자의 지속적인 소형화를 가져왔습니다. 이러한 미세화에는 1나노미터 이하의 형상을 평가할 수 있는 고도의 계측 및 검사 기술이 필요합니다. 소자의 미세화에 따라 미세한 결함이나 편차가 소자의 성능에 큰 영향을 미칠 수 있기 때문에 정밀하고 정확한 계측은 품질 관리와 수율 관리에 매우 중요합니다.

최근 반도체 계측 및 검사 기술의 혁신은 반도체 소자의 크기가 점점 작아지고 제조 공정이 복잡해짐에 따라 발생하는 문제를 해결하는 데 있어 매우 중요한 역할을 하고 있습니다. 이러한 발전은 현대 전자제품의 핵심인 반도체 부품의 품질, 성능 및 신뢰성을 보장하는 데 필수적입니다.

인공지능(AI)과 머신러닝(ML)은 결함 검출 및 분류의 속도, 정확성, 효율성을 향상시킴으로써 반도체 계측 및 검사에 혁명을 일으키고 있습니다. 이러한 기술은 검사 과정에서 생성되는 방대한 양의 데이터를 분석하여 잠재적인 결함이나 품질 문제를 나타낼 수 있는 패턴과 이상을 식별할 수 있게 해주며, AI 알고리즘은 과거 데이터로부터 학습하여 결함을 예측하고 식별할 수 있기 때문에 수작업 검사에 소요되는 시간과 비용을 절감하고 수율을 높일 수 있습니다.

이 보고서는 반도체 검사 및 계측 시장에 대한 포괄적이고 상세한 분석을 제공합니다. 광범위한 조사, 업계 전문 지식, 시장 인사이트를 바탕으로 검사 및 계측 분야의 현재와 향후 전망에 대한 전반적인 견해를 제공합니다.

Semiconductor metrology and inspection play crucial roles in ensuring the quality, reliability, and performance of semiconductor devices. Several driving forces propel advancements and investments in this field.

Overall, the semiconductor industry's relentless pursuit of innovation, coupled with increasing performance and quality expectations, drives continuous advancements in metrology and inspection technologies. These tools are essential for enabling the development and production of cutting-edge semiconductor devices that power modern electronics.

Process Control and Throughput: As semiconductor manufacturing processes become more complex, the need for real-time process control increases. Advanced metrology and inspection systems enable manufacturers to monitor processes closely and make immediate adjustments to ensure optimal performance and throughput. This real-time feedback loop is essential for maintaining the delicate balance between precision manufacturing and production efficiency.

Technological Advancements and Miniaturization: The pursuit of Moore's Law, which predicts a doubling of transistors on a microchip approximately every two years while decreasing cost, has led to the continual miniaturization of semiconductor devices. This miniaturization necessitates advanced metrology and inspection techniques capable of characterizing features at the nanometer scale and below. As devices shrink, even the smallest defects or variations can have a significant impact on device performance, making precise and accurate measurements critical for quality control and yield management.

Complex 3D Structures and New Materials: The evolution of semiconductor devices includes not just shrinking sizes but also increasing complexity in device architecture, such as 3D NAND flash memory and FinFET transistors. These complex structures improve performance and storage capacity but introduce new challenges in measurement and inspection. Additionally, the integration of new materials with unique properties necessitates the development of novel metrology tools capable of accurately assessing material characteristics without damaging the delicate structures.

Yield Optimization: In the highly competitive semiconductor industry, optimizing yield-the percentage of devices on a wafer that function correctly-is crucial for economic viability. Metrology and inspection are integral to identifying process variations and defects early in the manufacturing process, allowing for adjustments that minimize waste and improve yield. The ability to precisely measure and control the production process leads to significant cost savings and higher profitability.

Quality and Reliability Standards: The end applications of semiconductor devices, particularly in critical areas such as automotive, medical, and aerospace industries, demand the highest levels of quality and reliability. This demand requires stringent quality control measures throughout the manufacturing process, supported by sophisticated metrology and inspection techniques. These tools ensure that devices meet the rigorous standards required for their intended applications, minimizing the risk of failures that could have severe consequences.

Recent innovations in semiconductor metrology and inspection technologies have been pivotal in addressing the challenges posed by the ever-decreasing size of semiconductor devices and the complexity of their manufacturing processes. These advancements are critical for ensuring the quality, performance, and reliability of semiconductor components, which are the backbone of modern electronics. Here's an overview of some of the significant innovations in this field:

Artificial intelligence (AI) and machine learning (ML) are revolutionizing semiconductor metrology and inspection by improving the speed, accuracy, and efficiency of defect detection and classification. These technologies enable the analysis of vast amounts of data generated during the inspection process, identifying patterns and anomalies that may indicate potential failures or quality issues. AI algorithms can learn from historical data to predict and identify defects, reducing the time and cost associated with manual inspection and increasing yield rates.

High-resolution imaging techniques have seen substantial advancements, including electron microscopy (EM), atomic force microscopy (AFM), and X-ray tomography. These methods provide detailed views of semiconductor devices at the nanometer scale, allowing for precise characterization of features and defects. For instance, electron beam microscopy can now offer images at resolutions sufficient to inspect the atomic structure of materials, crucial for understanding complex 3D device architectures.

Multi-beam inspection systems use multiple electron beams simultaneously to inspect semiconductor wafers. This approach significantly increases throughput compared to traditional single-beam systems, enabling more comprehensive and faster inspections. Multibeam systems are particularly effective in identifying defects in complex patterns and multilayer structures, essential for ensuring the quality of advanced semiconductor devices.

Three-dimensional metrology technologies have become increasingly important for measuring the dimensions and profiles of complex 3D structures in semiconductor devices, such as FinFETs and 3D NAND flash memory. Techniques such as 3D X-ray microscopy (XRM) and 3D scanning electron microscopy (SEM) provide detailed volumetric measurements, offering insights into the quality and integrity of these structures.

The integration of metrology equipment directly into semiconductor fabrication tools allows for real-time process monitoring and control. This inline metrology approach enables immediate feedback and adjustments, reducing the cycle time for process optimization and significantly improving the efficiency of the manufacturing process. Integrated metrology systems utilize various measurement techniques, including optical, electrical, and material characterization methods, to ensure process stability and performance.

Advanced spectroscopic techniques, such as Raman spectroscopy and ellipsometry, have been refined for semiconductor metrology, providing non-destructive ways to analyze material properties, including composition, thickness, and refractive index. These techniques are invaluable for characterizing thin films, multi-layer stacks, and new materials being introduced in semiconductor manufacturing.

The use of big data analytics in semiconductor metrology and inspection involves processing and analyzing the vast amounts of data generated during the manufacturing process. This analysis helps identify trends, predict failures, and optimize manufacturing processes. Big data tools enable the correlation of data across different stages of production, improving overall yield and device performance.

Non-contact inspection methods, such as terahertz imaging and ultrasonic scanning, are being developed to inspect semiconductor wafers and devices without risking damage. These methods are particularly useful for inspecting delicate structures and materials, offering a safer alternative to traditional contact-based inspection techniques.

In today's semiconductor industry, where innovation and precision are paramount, the importance of inspection and metrology cannot be overstated. As semiconductor devices continue to evolve at a rapid pace, with shrinking feature sizes, increasing complexity, and growing demands for reliability and performance, the need for robust inspection and metrology solutions has never been greater. These technologies serve as the cornerstone of quality assurance in semiconductor manufacturing, enabling the detection of defects, measurement of critical dimensions, and characterization of materials at the nanoscale level.

As the semiconductor landscape undergoes profound transformations driven by technological advancements, shifting market dynamics, and evolving customer requirements, staying abreast of the latest trends, developments, and challenges in inspection and metrology is essential for industry stakeholders. Whether you are a semiconductor manufacturer striving to optimize production processes, a supplier seeking to develop innovative solutions, a researcher exploring cutting-edge technologies, or an investor evaluating market opportunities, a comprehensive understanding of the semiconductor inspection and metrology landscape is indispensable.

Against this backdrop, this report offers a comprehensive and in-depth analysis of the semiconductor inspection and metrology market. Drawing on extensive research, industry expertise, and market insights, this report provides a holistic view of the current state and future prospects of the inspection and metrology sector. From emerging trends and technological innovations to competitive dynamics and growth opportunities, this report covers a wide range of topics essential for industry professionals and decision-makers.

Key areas of focus include the latest advancements in inspection and metrology technologies, market trends and drivers shaping industry growth, competitive landscape and key players' strategies, regulatory and standards landscape, and future outlook and growth prospects. By leveraging actionable insights and strategic recommendations provided in this report, stakeholders can gain a competitive edge, identify growth opportunities, mitigate risks, and make informed decisions to drive success in the dynamic and fast-paced semiconductor inspection and metrology market.

In summary, this report serves as an indispensable resource for anyone looking to navigate the complexities of the semiconductor inspection and metrology landscape. Whether you are seeking to understand market dynamics, evaluate competitive positioning, identify growth opportunities, or formulate strategic plans, this report equips you with the insights and analysis needed to succeed in the ever-evolving semiconductor industry.

This 300-page report offers a complete analysis of the Process Control market, segmented as:

Includes excel spreadsheet of market revenues of each competitor in 22 segments from 2012 to 2023.