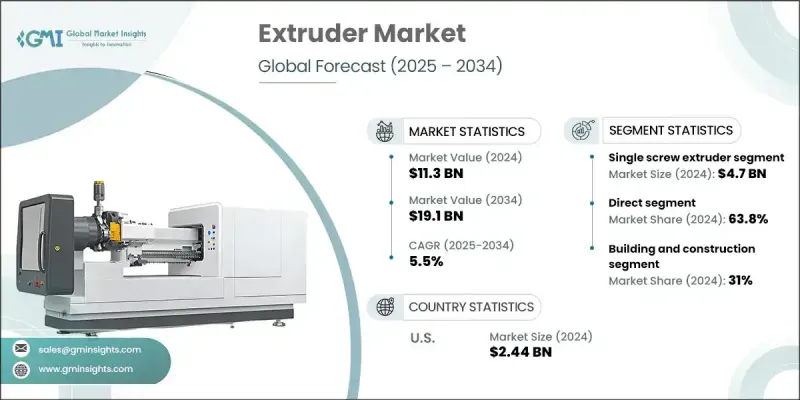

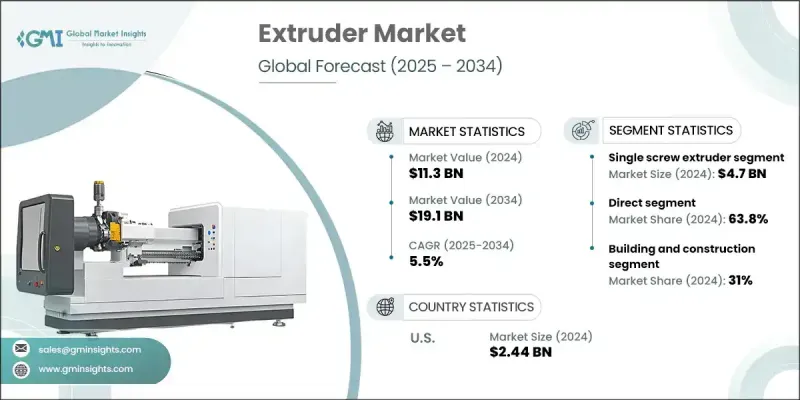

세계 압출기 시장은 2024년에 113억 달러로 평가되었으며 CAGR 5.5%로 성장하여, 2034년에는 191억 달러에 이를 것으로 추정됩니다.

시장 성장은 지속가능하고 편리한 솔루션을 추구하는 소비자의 선호도가 높아짐에 따라 패키징 분야에서 압출 시스템 수요 증가로 뒷받침됩니다. 식품, 의약품, 소비재 등의 업계에서 플라스틱 필름, 시트, 연포장의 사용이 증가하고 있는 것이 압출기의 채택을 가속화하고 있습니다. 유통기한의 연장, 안전성 향상, 혁신적인 포장 형태에 대한 기대 증가가 첨단 기계의 필요성을 밀어 올리고 있습니다. 지속가능성에 대한 관심이 높아짐에 따라 업계는 친환경 공정과 재료를 채택하고 있으며, 이러한 추세는 에너지 사용과 재료 폐기를 줄이는 압출 기술에 대한 투자를 촉구하고 있습니다. 시장 관계자는 일관성을 강화하고 운전 비용을 절감하며 고품질 제품을 제공하는 업그레이드를 선호합니다. 이와 병행하여, Industry 4.0 기술과 자동화의 통합은 생산 워크플로우를 더욱 현대화하고 효율성을 촉진합니다. 에너지 효율적인 설계, 향상된 스크류 및 배럴 시스템, 스마트 제어는 제조업을 재구성하고 업계 전반의 수익성을 향상시키는 혁신 중 하나입니다.

| 시장 범위 | |

|---|---|

| 시작 연도 | 2024년 |

| 예측 연도 | 2025-2034년 |

| 시장 규모 | 113억 달러 |

| 예측 금액 | 191억 달러 |

| CAGR | 5.5% |

싱글 스크류 압출기 부문은 2024년에 47억 달러를 생산했고 2034년까지 연평균 복합 성장률(CAGR)은 5.2%를 보일 것으로 예측됩니다. 이러한 제품 유형은 다양한 유형의 열가소성 플라스틱을 처리할 수 있는 범용성과 시트, 파이프 및 필름 생산의 효과로 인해 여전히 높은 수요가 있습니다. 제조업체는 신뢰성, 유지 보수 및 비용 효율성을 높이기 위해 싱글 스크류 모델을 계속 지원합니다. 이러한 특징은 성능을 저하시키지 않고 연속 운전이 가능하기 때문에 단순성과 내구성이 매일 생산에 빠뜨릴 수 없는 소규모 대규모 산업 용도에 적합합니다.

직접 판매 부문은 2024년에 63.8%의 점유율을 차지하며, 2034년까지 연평균 복합 성장률(CAGR)은 5.6%를 보일 것으로 예측됩니다. 많은 제조업체와 대규모 최종 사용자는 직접 거래를 선호합니다. 왜냐하면, 직접 거래를 실시하는 것으로, 세세한 지원, 상세한 커스터마이즈·옵션, 설치나 기술 서비스의 신속한 대응이 가능하게 되기 때문입니다. 이 채널은 압출기 제조업체에게 생산 수요에 맞는 개별 솔루션을 제공하면서 장기적인 고객 관계를 구축할 수 있는 기회를 제공합니다. 생산이 복잡해짐에 따라 커스터마이즈된 기계와 실용적인 지원의 필요성이 커지고 있으며, 직접 판매 접근법은 시장 확대의 중요한 부분이 되었습니다.

미국의 압출기 시장은 2024년에 24억 4,000만 달러를 생산했고, 2034년까지의 CAGR은 5.2%를 나타낼 전망입니다. 미국의 성장은 그 성숙한 제조 인프라와 건설, 자동차, 소비재, 포장 등 주요 부문 수요 증가에 크게 뒷받침되고 있습니다. 미국 기업은 또한 기술 업그레이드 및 생산 라인 전체의 자동화 통합에 많은 투자를 하고 있습니다. 미국에서는 지속가능성과 재활용에 중점을 두는 경향이 강하며 친환경 소재를 지원하는 압출 성형 공정이 선호되는 경향이 있습니다. 세계적으로 인정받은 압출기 제조업체의 존재와 지속적인 혁신의 노력으로 미국은 세계 시장에서 주요 기업로서의 입지를 더욱 강화하고 있습니다.

압출기 세계 시장의 주요 기업으로는 Milacron, Kabra Extrusion Technik Ltd., Hosokawa Alpine American, Inc., Coperion GmbH, Reading Bakery Systems, Cowell Extrusion Machinery Co.Ltd., Entek, Anderson Feed Technology, Bausano & Figli SpA Maschinenfabrik, EXTRUDEX Kunststoffmaschinen GmbH,Shibaura Machine, R& B Plastics Machinery, LLC, BC Extrusion Holding GmbH, Davis-Standard, Everplast, Clextral, KraussMaffei Berstorff, Presezzi Extrusion SpA등이 있습니다. 시장 포지션을 강화하기 위해 압출기 업계의 기업은 혁신, 업무 효율성, 고객 중심 접근법을 강조합니다. 대부분은 지속가능성 목표에 따라 에너지 효율적인 기계와 스마트 제어 시스템을 도입하여 제품 포트폴리오를 확대하고 있습니다. 전략적 파트너십과 인수도 제조업체가 지리적 범위를 넓히고 새로운 응용 분야에 진입하는 데 도움이 됩니다. 선도적인 제조업체는 보다 다재다능한 압출 기술을 개발하고 재료 취급 능력을 향상시키기 위해 연구 개발에 투자하고 있습니다. 또한 식품 가공, 플라스틱, 건설 등의 업계 특유의 요구에 대응하기 위해, 커스터마이즈에도 힘을 쏟고 있습니다.

The Global Extruder Market was valued at USD 11.3 billion in 2024 and is estimated to grow at a CAGR of 5.5% to reach USD 19.1 billion by 2034.

Market growth is being supported by the increasing demand for extrusion systems in the packaging sector, driven by the rise in consumer preference for sustainable and convenient solutions. The growing use of plastic films, sheets, and flexible packaging across industries such as food, pharmaceuticals, and consumer goods is accelerating the adoption of extruders. Evolving expectations for longer shelf life, better safety, and innovative packaging formats have pushed the need for advanced machinery. As sustainability concerns become more prominent, industries are adopting eco-friendly processes and materials, and this trend is also encouraging investments in extrusion technologies that reduce energy use and material waste. Market players are prioritizing upgrades that enhance consistency, reduce operational costs, and deliver high-quality output. Alongside this, the integration of Industry 4.0 technologies and automation is further modernizing production workflows and driving efficiency. Energy-efficient designs, improved screw and barrel systems, and smart controls are among the innovations that are reshaping manufacturing and improving profitability across industries.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $11.3 Billion |

| Forecast Value | $19.1 Billion |

| CAGR | 5.5% |

The single screw extruders segment generated USD 4.7 billion in 2024 and is expected to grow at a CAGR of 5.2% through 2034. These systems remain in high demand due to their versatility in processing different types of thermoplastics and their effectiveness in the production of sheets, pipes, and films. Manufacturers continue to favor single screw models for their reliability, reduced maintenance, and cost-efficiency. These features allow for continuous operation without compromising performance, making them suitable for both small- and large-scale industrial applications where simplicity and durability are critical to daily production.

The direct sales segment held a 63.8% share in 2024 and is anticipated to grow at a 5.6% CAGR through 2034. Many manufacturers and large-scale end use prefer to engage in direct transactions, as it gives them access to tailored support, detailed customization options, and faster response times for installation and technical servicing. This channel offers extruder producers an opportunity to build long-term client relationships while delivering personalized solutions that match exact production demands. As production complexity increases, the need for customized machinery and hands-on support has made the direct sales approach a critical part of market expansion.

U.S. Extruder Market generated USD 2.44 billion in 2024, with a 5.2% CAGR through 2034. Growth in the U.S. is largely backed by its mature manufacturing infrastructure and increasing demand from key sectors such as construction, automotive, consumer goods, and packaging. U.S.-based companies are also investing heavily in upgrading technologies and integrating automation across production lines. The country's strong focus on sustainability and recycling is fostering a preference for extrusion processes that support eco-friendly materials. The presence of globally recognized extruder producers and ongoing innovation efforts further position the U.S. as a key player in the global market.

Prominent companies in the Global Extruder Market include Milacron, Kabra Extrusion Technik Ltd, Hosokawa Alpine American, Inc., Coperion GmbH, Reading Bakery Systems, Cowell Extrusion Machinery Co., Ltd., Entek, Anderson Feed Technology, Bausano & Figli S.p.A., Leistritz, BREYER GmbH Maschinenfabrik, EXTRUDEX Kunststoffmaschinen GmbH, Shibaura Machine, R&B Plastics Machinery, LLC, BC Extrusion Holding GmbH, Davis-Standard, Everplast, Clextral, KraussMaffei Berstorff, and Presezzi Extrusion S.p.A. To strengthen their market position, companies in the extruder industry are emphasizing innovation, operational efficiency, and customer-centric approaches. Many are expanding their product portfolios by introducing energy-efficient machines and smart control systems that align with sustainability goals. Strategic partnerships and acquisitions are also helping manufacturers broaden geographic reach and enter new application areas. Leading players are investing in R&D to develop more versatile extrusion technologies and improve material handling capabilities. Customization is another major focus, allowing companies to meet the unique needs of industries such as food processing, plastics, and construction.