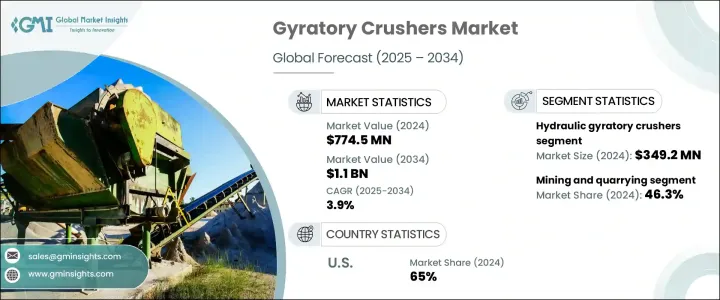

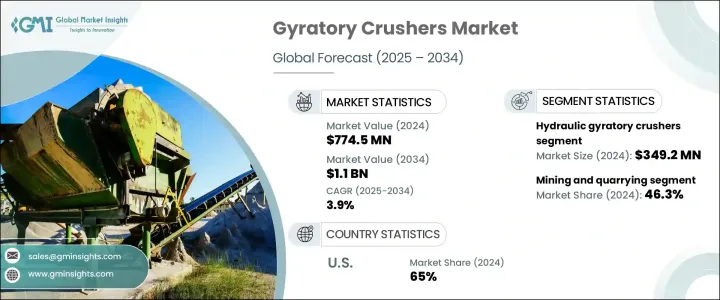

세계의 선회식 파쇄기 시장은 2024년에는 7억 7,450만 달러에 달했고, CAGR 3.9%로 성장할 전망이며, 2034년에는 11억 달러에 이를 것으로 추정됩니다.

특히 개발도상국에서의 광물 및 골재 수요 증가가 광업 기업의 생산 확대를 뒷받침하고 있습니다. 선회식 파쇄기는 대용량의 광석 처리 능력을 제공하기 때문에 이 확대에 있어서 중심적인 역할을 하고 있습니다. 이 기계들은 대량의 원료를 효율적으로 파쇄하기 위해 필수적이며 채굴 기술이 발전함에 따라 점점 수요가 높아지고 있습니다. 인프라의 성장과 급속한 도시화로 건설용 골재의 요구가 크게 높아지고 있습니다.

다리, 고속도로, 상업개발 등 대규모 프로젝트가 구체화됨에 따라 단단한 암석에서 골재를 생산할 수 있는 파쇄 시스템이 불가결해지고 있습니다. 자동화, 내마모성 컴포넌트, 에너지 절약 시스템 등 파쇄기 설계의 혁신은 기계의 성능, 안전성 및 전체 조업 생산량을 향상시키고 있습니다. 스마트 기능의 통합은 신뢰성을 높이는 동시에 계획되지 않은 다운타임을 줄이고 확장 가능하고 효율적인 재료 처리에 대한 진화하는 업계의 요구에 부합합니다.

| 시장 범위 | |

|---|---|

| 시작 연도 | 2024년 |

| 예측 연도 | 2025-2034년 |

| 시작 금액 | 7억 7,450만 달러 |

| 예측 금액 | 11억 달러 |

| CAGR | 3.9% |

2024년 유압 선회식 파쇄기 부문은 3억 4,920만 달러의 매출을 기록했습니다. 이러한 시스템은 구리나 철 채굴과 같은 대규모 광석의 환원을 필요로 하는 산업에서 널리 사용되고 있으며 화강암과 같은 매우 연마성이 높은 원료를 다루도록 설계되었습니다. 유압을 장비하고 조정, 유지보수, 과부하 대응 등의 중요한 기능을 효율화합니다. 이를 통해 사용법이 간소화될 뿐만 아니라 기계의 안전성과 가동 시간이 향상됩니다. 오퍼레이터는 파쇄기 설정을 실시간으로 쉽게 조정할 수 있기 때문에 안정적인 출력을 유지하고 처리 능력을 최적화할 수 있습니다. 유압 시스템은 또한 신속한 챔버 클리어와 부품 교환을 가능하게 하여 중단을 최소화하고 수작업 필요없이 생산성을 향상시킵니다.

2024년 시장 점유율은 광업 및 채석 부문이 46.3%를 차지했습니다. 이 부문은 처리되는 재료의 양과 경도로 인해 선회식 파쇄기로부터 큰 혜택을 받고 있습니다. 이 기계들은 구리, 철, 석회암, 화강암과 같은 단단한 광물의 1차 파쇄에 적합합니다. 견고한 구조와 높은 처리 능력으로 연속적이고 대규모 머티리얼 핸들링을 필요로 하는 작업에 매우 적합합니다. 선회식 파쇄기는 원료 광석의 크기를 줄이는 효율을 확보하고 안정적인 원료로 하류 공정을 지원합니다.

미국 선회식 파쇄기 시장은 2024년에 65%의 점유율을 차지했으며 광업 및 채석 부문 확대에 견인되었습니다. 분쇄기는 높은 출력과 신뢰성으로 쇄석, 자갈, 모래와 같은 골재 처리에 널리 적용됩니다. 통합 자동화 및 유압 제어 기능을 갖춘 파쇄기의 지속적인 개발로 유지보수 수요를 줄이면서 성능이 향상되었습니다. 이러한 발전은 장비의 수명주기를 개선하고 운영 비용을 줄이는 데 매우 중요합니다. 또한, 도로와 도시 확장 프로젝트를 포함한 인프라 개발의 추진이 증가하고 있기 때문에 대량의 골재 생산에 대응하는 대용량 파쇄기의 요구가 높아지고 있습니다.

세계의 선회식 파쇄기 시장을 형성하고 있는 주요 제조업체로는 ThyssenKrupp AG, TAKRAF GmbH, Weir Group, Shanghai SANME Mining Machinery Corp Ltd, FLSmidth & Co. A/S, Earthtechnica, XCMG, AGICO Cement Machinery Co Ltd, The Makuri Group, Shunda Mining Group Co Ltd, Terex Corporation, Sandvik AB, Metso Outotec, CITIC Heavy Industries Co., Ltd. 및 Propel Industries입니다. 업계 선두는 자동화, 에너지 효율, 디지털 통합에 중점을 둔 전략적 제품 혁신을 통해 시장에서의 입지를 강화하고 있습니다.

제조업체 각사는 연구개발에 투자하여 실시간 성능 감시 및 적응 처리를 가능하게 하는 스마트 제어 시스템을 갖춘 파쇄기를 개발하고 있습니다. 신흥 지역의 생산 능력 확대로 보다 신속한 납품 및 지역 밀착형 지원이 가능해집니다. 기업은 또, 고객과의 장기적인 관계를 쌓기 위해서, 예지 보전 및 원격 진단 등의 애프터 서비스를 강화하고 있습니다. 광산 회사나 건설 회사와의 파트너십은 특정 현장 조건에 맞춘 맞춤형 파쇄 솔루션의 공동 개발에 도움이 되고 있습니다.

The Global Gyratory Crushers Market was valued at USD 774.5 million in 2024 and is estimated to grow at a CAGR of 3.9% to reach USD 1.1 billion by 2034. Rising demand for minerals and aggregates, particularly in developing countries, is driving mining firms to ramp up production. Gyratory crushers play a central role in this expansion, as they offer high-capacity ore processing capabilities. These machines are essential for crushing large volumes of raw material efficiently and are increasingly sought after with advancements in extraction technology. Infrastructure growth and rapid urbanization are significantly increasing the need for construction aggregates.

As large-scale projects such as bridges, highways, and commercial developments take shape, crushing systems capable of producing aggregates from hard rocks become indispensable. Innovations in crusher design, including automation, wear-resistant components, and energy-saving systems, are improving machine performance, safety, and overall operational output. The integration of smart features is enhancing reliability while reducing unplanned downtime, aligning with evolving industry needs for scalable and efficient material processing.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $774.5 Million |

| Forecast Value | $1.1 Billion |

| CAGR | 3.9% |

In 2024, the hydraulic gyratory crushers segment generated USD 349.2 million, driven by offering advanced capabilities in heavy-duty material processing. These systems are widely used in industries requiring large-scale ore reduction, such as copper and iron extraction, and are designed to handle extremely abrasive feedstocks like granite. Equipped with hydraulics, they streamline critical functions such as adjustment, maintenance, and overload response. This not only simplifies usage but also boosts machine safety and uptime. Operators can easily adjust crusher settings in real time to maintain consistent output and optimize throughput. Hydraulic systems also enable fast chamber clearing and part replacements, minimizing interruptions and enhancing productivity without the need for manual labor.

The mining and quarrying segment accounted for 46.3% market share in 2024. This segment benefits significantly from gyratory crushers due to the volume and hardness of the materials processed. These machines are the preferred choice for the primary crushing of hard minerals such as copper, iron, limestone, and granite. Their robust construction and high throughput capabilities make them ideal for operations that require continuous, large-scale material handling. Gyratory crushers ensure efficiency in reducing the size of raw ore, supporting downstream processes with consistent feedstock.

United States Gyratory Crushers Market held a 65% share in 2024, led by expansion in the mining and quarrying sectors. The machines are widely applied in processing aggregates like crushed stone, gravel, and sand due to their high output and reliability. Continuous development of crushers featuring integrated automation and hydraulic controls has enhanced performance while lowering maintenance demands. These advancements are crucial in improving the equipment lifecycle and reducing operational costs. Furthermore, the growing push for infrastructure development, including roads and urban expansion projects, is fueling the need for large-capacity crushers that meet the demands of heavy aggregate production.

Major manufacturers shaping the Global Gyratory Crushers Market include ThyssenKrupp AG, TAKRAF GmbH, Weir Group, Shanghai SANME Mining Machinery Corp Ltd, FLSmidth & Co. A/S, Earthtechnica, XCMG, AGICO Cement Machinery Co Ltd, The Makuri Group, Shunda Mining Group Co Ltd, Terex Corporation, Sandvik AB, Metso Outotec, CITIC Heavy Industries Co., Ltd., and Propel Industries. Industry leaders are strengthening their market position through strategic product innovation, focusing on automation, energy efficiency, and digital integration.

Manufacturers are investing in R&D to develop crushers with smart control systems, allowing real-time performance monitoring and adaptive processing. Expansion of production capacity in emerging regions enables faster delivery and localized support. Companies are also enhancing after-sales services such as predictive maintenance and remote diagnostics to build long-term relationships with clients. Partnerships with mining and construction firms help co-develop customized crushing solutions tailored to specific site conditions.