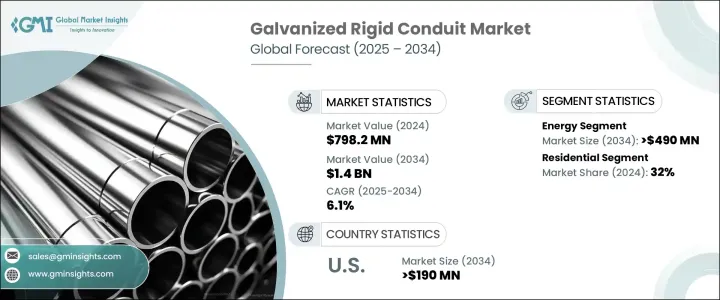

세계의 아연 도금 경질 도관 시장은 2024년에는 7억 9,820만 달러로 평가되었고, 건설 기술의 진보, 인프라의 현대화, 엄격한 안전 규제에 추진되어, CAGR 6.1%로 성장할 전망이며, 2034년에는 14억 달러에 이를 것으로 예측되고 있습니다.

강도와 내식성을 갖춘 보호 전선관에 대한 수요는 상업, 시설, 공업의 각 분야에서 높아지고 있습니다. 코팅이나 제조 공정의 혁신에 의해 이러한 제품의 기능 성능이 향상해, 고객에게 보다 매력적인 것이 되고 있습니다. 또한, 도시화와 산업의 확대가 새로운 시장을 개척하고 있는 한편, 환경의 지속 가능성이 중시되어 전선관 제조에 있어서 재활용 가능한 재료의 사용이 촉진되고 있습니다.

이러한 긍정적인 동향에도 불구하고 시장은 이익률에 영향을 미칠 수 있는 원재료 가격의 변동 및 엄격한 규제 관리와 같은 과제에 직면하고 있습니다. 철강 관세 부과는 원자재 비용을 더욱 상승시켜 아연 도금 경질 도관의 가격 설정에 영향을 주고 공급망에 불안정성을 초래할 수 있습니다. 그러나 인프라에 대한 지속적인 투자와 엄격한 전기 안전 기준 준수로 시장 성장은 유지될 것으로 예상됩니다.

| 시장 범위 | |

|---|---|

| 시작 연도 | 2024년 |

| 예측 연도 | 2025-2034년 |

| 시작 금액 | 7억 9,820만 달러 |

| 예측 금액 | 14억 달러 |

| CAGR | 6.1% |

에너지 부문은 발전 및 배전 시스템에서 내구성과 신뢰성이 높은 도관 솔루션의 필요성으로 인해 2034년까지 4억 9,000만 달러를 생산할 것으로 예측됩니다. 이러한 도관은 고전압 환경에서의 배선 보호에 필수적이며, 기존의 에너지 인프라 및 신재생 에너지 인프라 모두에서 채택되고 있습니다. 송전망의 근대화 프로젝트가 세계적으로 기세를 늘리는 가운데, 내부식성으로 오래가는 아연 도금 도관에 대한 수요는 계속 증가하고 있습니다.

주택용 부문은 2024년에 32%의 점유율을 차지했으며, 2034년까지 연평균 복합 성장률(CAGR) 5.5%를 보일 것으로 예측됩니다. 이는 건설활동 증가와 전기안전에 대한 관심이 높아져 내화성 도관의 채용으로 이어졌습니다. 스마트홈의 대두도 신뢰성 높은 전기 시스템에 대한 수요를 높여 시장 확대에 더욱 기여하고 있습니다. 현대의 주택에서는 디지털 가전, 보안 시스템, 홈 자동화를 지원하기 위해 안전하고 대용량의 전기 네트워크가 필요하며, 이들은 모두 아연 도금 경질 도관에 의한 보호 혜택을 받고 있습니다.

미국의 아연 도금 경질 도관 인프라의 근대화, 안전 규제, 전기 그리드 요건으로 2024년 시장 규모는 1억 1,870만 달러에 달했습니다. 제조 개선과 기술 진보가 제품 효율을 높이고 시장 성장을 뒷받침하고 있습니다. 국내 수요는 견조한 건설 활동, 노후 건조물의 개수 증가, 지속 가능성 중시 강화에 의해 더욱 뒷받침되고 있습니다. 스마트 빌딩 건설 및 신재생 에너지 설치의 확대는, 아연 도금 경질 도관의 수요를 한층 더 강화하고 있습니다.

세계의 아연 도금 경질 도관 시장의 주요 기업은 Atkore, Schneider Electric, Legrand, Nucor Tubular Products, Zekelman Industries 등입니다. 이러한 기업은 시장에서의 존재감을 높이기 위해 기술 혁신, 지속가능성, 고객 참여에 주력하고 있습니다. 전략적 접근법에는 첨단 제조 기술에 대한 투자, 친환경 관행 채택, 다양한 고객 요구에 대응하기 위한 제품 포트폴리오 확대 등이 포함됩니다. 시장의 동향 및 규제 기준에 맞추어, 이러한 기업은 진화하는 아연 도금 경질 도관 시장에서 경쟁력을 유지하는 것을 목표로 하고 있습니다.

The Global Galvanized Rigid Conduit Market was valued at USD 798.2 million in 2024 and is estimated to grow at a CAGR of 6.1% to reach USD 1.4 billion by 2034, propelled by advancements in construction techniques, infrastructure modernization, and stringent safety regulations. The demand for protective electrical conduits that offer strength and corrosion resistance is increasing across commercial, institutional, and industrial sectors. Innovations in coating and manufacturing processes have enhanced the functional performance of these products, making them more appealing to customers. Additionally, urbanization and industrial expansion are opening new markets, while the emphasis on environmental sustainability is driving the use of recyclable materials in conduit manufacturing.

Despite these positive trends, the market faces challenges such as fluctuations in raw material prices and strict regulatory controls that can impact profit margins. The imposition of steel tariffs has further increased raw material costs, potentially affecting the pricing of galvanized rigid conduits and introducing volatility into supply chains. However, continued investment in infrastructure and adherence to rigorous electrical safety standards are expected to sustain market growth.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $798.2 Million |

| Forecast Value | $1.4 Billion |

| CAGR | 6.1% |

The energy sector is anticipated to generate USD 490 million by 2034, driven by the need for durable and reliable conduit solutions in power generation and distribution systems. These conduits are crucial for protecting wiring in high-voltage environments and are adopted in both traditional and renewable energy infrastructure. As grid modernization projects gain momentum globally, the demand for corrosion-resistant, long-lasting galvanized conduits continues to grow.

The residential segment accounted for a 32% share in 2024 and will grow at a CAGR of 5.5% through 2034, fueled by increased construction activities and a heightened focus on electrical safety, leading to the adoption of fire-resistant conduits. The rise of smart homes has also amplified the demand for dependable electrical systems, further contributing to market expansion. Modern residences now require secure, high-capacity electrical networks to support digital appliances, security systems, and home automation, all of which benefit from the protection provided by galvanized rigid conduits.

United States Galvanized Rigid Conduit Market was valued at USD 118.7 million in 2024 due to infrastructure modernization, safety regulations, and electrical grid requirements. Manufacturing improvements and technological advancements have enhanced product efficiency, supporting market growth. Domestic demand is further supported by robust construction activity, increased retrofitting of old structures, and a stronger emphasis on sustainability. The expansion of smart building construction and renewable energy installations further bolsters the demand for galvanized rigid conduits.

Key players in the Global Galvanized Rigid Conduit Market include Atkore, Schneider Electric, Legrand, Nucor Tubular Products, and Zekelman Industries. These companies are focusing on innovation, sustainability, and customer engagement to strengthen their market presence. Strategic approaches include investment in advanced manufacturing technologies, adoption of eco-friendly practices, and expansion of product portfolios to meet diverse customer needs. By aligning with market trends and regulatory standards, these companies aim to maintain a competitive edge in the evolving galvanized rigid conduit market.