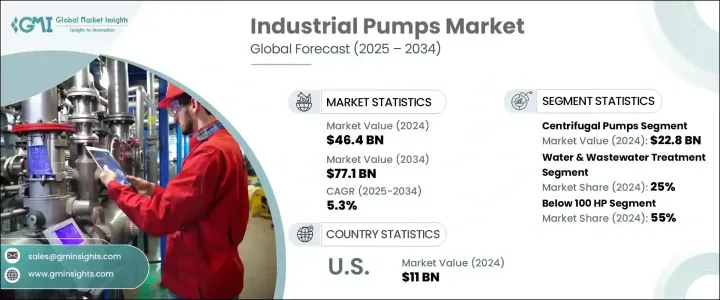

세계의 산업용 펌프 시장은 2024년 464억 달러로 평가되었으며, 2025년부터 2034년까지 연평균 복합 성장률(CAGR) 5.3%를 나타낼 것으로 예측됩니다.

이 성장의 주요 요인은 다양한 산업에서 수요 증가, 펌프 시스템의 기술 진보, 세계의 급속한 산업화입니다. 현재의 요구는 계속 증가하고 있으며, 석유, 가스, 폐수 처리, 광업, 화학 등의 분야에서의 용도가 증가하고 있는 것이 시장의 성장에 박차를 가하고 있습니다. 가능한 물 관리 기술로의 전환은 현대적이고 에너지 효율적인 펌프에 대한 요구를 더욱 강화하고 있습니다. 증가에 따라 산업용 펌프 수요가 급증하고 있습니다. 스마트팜프 기술과 IoT 대응 시스템의 채용이 업계 정세를 재구축하고 있으며, 산업계는 업무 효율의 향상과 에너지 소비의 삭감을 실현하고 있습니다.

시장은 원심 펌프, 용적 펌프, 다이어프램 펌프, 기어 펌프, 스크류 펌프 등을 포함한 펌프 유형별로 구분됩니다. 2024년 원심펌프 분야는 석유 및 가스, 물관리, 화학처리 등의 산업에서 널리 응용되었기 때문에 228억 달러를 창출하였습니다. 용적식 펌프는 점성이 높은 유체를 효율적으로 처리하는 것으로 알려져 있으며, 수압 파쇄에 있어서의 사용 증가나 노후화된 인프라의 갱신에 의해 꾸준한 성장이 전망되고 있습니다. 이 동향은 특히 에너지 부문에 많은 투자를 하고 있는 국가에서 두드러지며, 고성능 펌프는 채굴, 정제, 운송 공정 최적화에 필수적입니다. 산업계가 생산성 향상과 다운타임 최소화에 주력하는 동안 신뢰성과 운전 효율을 제공하는 고급 펌프 시스템에 대한 수요는 계속 증가하고 있습니다.

| 시장 범위 | |

|---|---|

| 시작 연도 | 2024년 |

| 예측 연도 | 2025-2034년 |

| 시작 금액 | 464억 달러 |

| 예측 금액 | 771억 달러 |

| CAGR | 5.3% |

산업용 펌프 시장은 또한 상하수도처리, 화학, 석유화학, 광업, 식음료, 건설, 석유 및 가스, 의약품, 해양, 펄프·제지, 기타 등 최종 이용 산업별로 구분됩니다. 2024년 시장 점유율은 상하수도 처리가 25%를 차지했지만, 이는 급속한 도시화와 산업 성장 속에서 청결한 물 관리에 대한 요구가 높아지고 있음을 반영한 것입니다. 개발도상 지역에서 인구가 증가함에 따라 효율적인 수처리 및 폐수 관리 솔루션의 필요성이 점점 높아지고 있습니다.

미국의 산업용 펌프 시장은 80%의 점유율을 차지하며, 2024년에는 110억 달러를 창출했습니다. 이송과 같은 공정에서 광범위하게 사용되는 산업용 펌프 수요를 크게 견인하고 있습니다. 또한, 광업 부문의 미국 경제에 대한 공헌은 건설, 자동차, 항공우주 등의 산업에 필수적인 재료를 공급하는 중요한 역할과 함께 산업용 펌프의 견조한 수요를 더욱 뒷받침하고 있습니다.

The Global Industrial Pumps Market, valued at USD 46.4 billion in 2024, is projected to grow at a CAGR of 5.3% from 2025 to 2034. This growth is primarily driven by rising demand across various industries, technological advancements in pumping systems, and rapid industrialization worldwide. As economies expand and manufacturing sectors thrive, the need for efficient, durable, and high-performance industrial pumps continues to escalate. Increasing applications in sectors such as oil and gas, water and wastewater treatment, mining, and chemicals are fueling market growth. Moreover, the transition toward sustainable water management practices, coupled with rising environmental regulations, has further elevated the need for modern and energy-efficient pumps. Emerging markets, especially in Asia Pacific and Latin America, are witnessing surging demand for industrial pumps due to rapid urbanization and increasing investments in infrastructure development. The adoption of smart pump technologies and IoT-enabled systems is reshaping the landscape, allowing industries to improve operational efficiency and reduce energy consumption.

The market is segmented by pump type, including centrifugal pumps, positive displacement pumps, diaphragm pumps, gear pumps, screw pumps, and others. In 2024, the centrifugal pumps segment generated USD 22.8 billion, owing to its widespread application in industries such as oil and gas, water management, and chemical processing. Positive displacement pumps, known for their efficiency in handling viscous fluids, are expected to witness steady growth, driven by increasing use in hydraulic fracturing and the replacement of aging infrastructure. This trend is particularly noticeable in countries investing heavily in their energy sectors, where high-performance pumps are essential for optimizing extraction, refining, and transportation processes. As industries focus on enhancing productivity and minimizing downtime, the demand for advanced pumping systems that offer reliability and operational efficiency continues to rise.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $46.4 Billion |

| Forecast Value | $77.1 Billion |

| CAGR | 5.3% |

The industrial pumps market is further segmented by end-use industries, including water and wastewater treatment, chemicals, petrochemicals, mining, food and beverages, construction, oil and gas, pharmaceuticals, marine, pulp and paper, and others. Water and wastewater treatment accounted for a 25% market share in 2024, reflecting the growing need for clean water management amid rapid urbanization and industrial growth. As population increases, especially in developing regions, the need for efficient water treatment and wastewater management solutions continues to intensify. Pumps also play a critical role in the mining industry, where dewatering pumps remove excess water from mines to ensure safety and operational efficiency. Additionally, the food and beverage sector relies heavily on specialized pumps for hygienic processing and maintaining product integrity.

The United States Industrial Pumps Market commanded an 80% share, generating USD 11 billion in 2024. This dominance is attributed to technological advancements, growing industrial activity, and an increasing focus on sustainable water management. The U.S. oil and gas industry, particularly shale oil production, remains a significant driver of demand for industrial pumps, which are used extensively in processes such as extraction, refining, and transportation. Additionally, the mining sector's contributions to the U.S. economy, coupled with its critical role in supplying essential materials to industries like construction, automotive, and aerospace, further support the robust demand for industrial pumps.