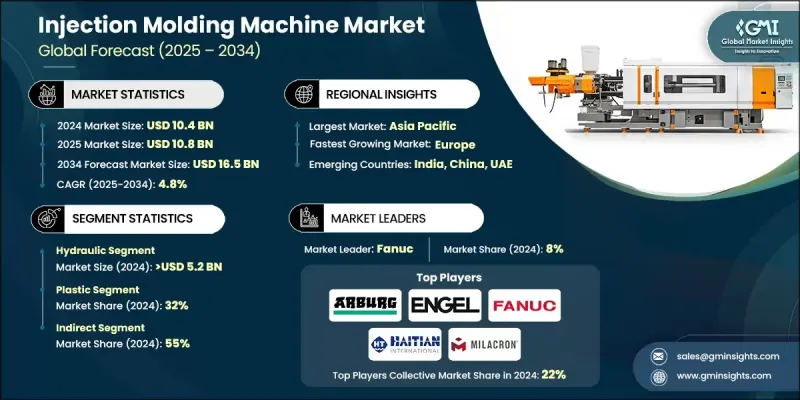

세계의 사출 성형기 시장은 2024년 104억 달러로 평가되었으며 CAGR 4.8%로 성장했으며 2034년에는 165억 달러에 이를 것으로 추정됩니다.

시장 성장은 주요 제조 부문에서 가볍고 고성능 플라스틱 부품에 대한 수요 증가를 뒷받침하고 있습니다. 산업은 효율성을 높이고 운영 비용을 줄이는 재료로 전환하고 있습니다. 예를 들어, 운송과 항공우주에서 부품의 경량화는 연비 향상과 배출 가스 감소를 초래합니다. 사출 성형기는 내구성과 경량을 모두 갖춘 복잡한 부품을 생산할 때 정밀도와 재현성을 제공하며 여기에서 중요한 역할을 수행합니다. 최종 용도가 더 디자인성이 높아짐에 따라 제조업체는 더 높은 정확도, 빠른 사이클 타임 및 새로운 폴리머와의 호환성을 제공하는 기계에 눈을 돌리고 있습니다. 완벽한 출력과 신속한 납품이 중시되어 새로운 세대의 기계는 필수적인 업그레이드가 되었습니다. 기업은 현재 복잡한 금형과 다양한 자재관리에 대응할 수 있는 첨단 기술에 투자하여 신뢰성 높은 성능과 결함을 최소화하고 있습니다. 복잡하고 가벼운 재료를 사용하는 동향은 최첨단 사출 성형기에 대한 수요를 계속 형성하고 사출 성형기를 현대 제조 전략의 기본 부분으로 만듭니다.

| 시장 범위 | |

|---|---|

| 시작 연도 | 2024년 |

| 예측 연도 | 2025-2034년 |

| 시장 규모 | 104억 달러 |

| 예측 금액 | 165억 달러 |

| CAGR | 4.8% |

유압 사출 성형기 부문은 2024년 52억 달러에 이르고, 2034년까지 연평균 복합 성장률(CAGR) 4.8%를 보일 것으로 예측됩니다. 유압 사출 성형기는 신뢰성과 초기 비용이 낮기 때문에 더 크고 무거운 부품을 생산하는 데 적합합니다. 성장은 완만하지만, 널리 사용되고 있기 때문에 여전히 강한 지위를 유지하고 있습니다. 전동 사출 성형기는 에너지 효율 향상, 정밀도 향상, 소음 수준 감소, 유지 보수 요구 사항 감소 등의 이점을 제공하여 지속가능성과 운영 효율성을 중시하는 제조업체에게 호소하고 있습니다.

플라스틱 재료 부문은 2024년에 32%의 점유율을 차지하며 2025년부터 2034년까지 연평균 복합 성장률(CAGR) 4.4%를 보일 것으로 예측됩니다. 플라스틱이 계속해서 우위를 유지하고 있는 것은 범용성, 성형의 용이성, 소비재, 포장, 자동차 부품 등의 용도에 있어서 수요 증가가 관련되어 있습니다. 경량성과 비용 효과로 제품 설계와 대량 생산이 수익성에 중요한 역할을 하는 산업에서는 플라스틱이 최적의 선택이 되었습니다.

2024년 미국 사출 성형기 시장은 76%의 점유율을 차지했으며, 21억 5,000만 달러를 창출했습니다. 이 지역의 성장은 가볍고 정밀한 플라스틱 부품으로 이동하는 의료, 자동차, 포장 등 산업과 밀접한 관련이 있습니다. 기업은 생산성과 생산 품질을 향상시키는 최신 기계로 구식 장비를 대체하는 경향이 커지고 있습니다. 전동 기계와 하이브리드 기계의 채용이 급증하고 있는 것은 이 지역 전체에서 제조업에서의 자동화와 효율화의 역할이 확대되고 있는 것을 반영하고 있습니다.

세계 사출 성형기 산업의 진보를 견인하는 주요 기업으로는 Milacron, Haitian International, ENGEL, JSW, KraussMaffei, Yizumi, Fanuc, Nissei Plastic Industrial, Sumitomo, Shibaura Machine, Toyo Machinery & Metal, Wittmann Battenfeld, Arburg, Husky Injection Molding Systems, Chen Hsong Holdings 등이 있습니다. 이러한 기업들은 지속적으로 혁신, 자동화, 시스템 통합에 주력하고 있습니다. 사출 성형기 시장의 선두 기업은 생산 효율을 높이기 위해 스마트 제조 기술과 자동화 도입에 주력하고 있습니다. 지속가능한 솔루션에 대한 수요 증가에 대응하기 위해 에너지 효율적인 모델과 완전 전기화 모델에 대한 투자가 크게 늘어나고 있습니다. 각 기업은 특히 의료기기 및 전자기기와 같은 고정밀 분야에서 복잡한 용도를 지원하기 위해 제품 라인을 지속적으로 확장하고 있습니다. 전략적 파트너십과 협력 관계는 기업이 특정 지역 수요에 대응하는 현지화된 솔루션을 개발하는 데 도움이 됩니다. 주요 기업은 또한 디지털 인터페이스를 업그레이드하고, IoT를 통합하고, 더 나은 기계 진단을 제공하며, 다운타임을 줄이기 위해 원격 모니터링 기능을 제공합니다.

The Global Injection Molding Machine Market was valued at USD 10.4 billion in 2024 and is estimated to grow at a CAGR of 4.8% to reach USD 16.5 billion by 2034.

Market growth is propelled by the increasing demand for lightweight and high-performance plastic components across key manufacturing sectors. Industries are shifting toward materials that enhance efficiency and cut down on operational costs. In transportation and aerospace, for instance, lighter parts translate into better fuel economy and reduced emissions. Injection molding machines play a critical role here, offering precision and repeatability in producing complex parts that are both durable and lightweight. As end-use applications become more design-intensive, manufacturers are turning to machines that offer higher precision, faster cycle times, and compatibility with newer polymers. The growing emphasis on flawless output and rapid delivery has made newer-generation machines an essential upgrade. Companies are now investing in advanced technologies that can handle intricate molds and varied materials, ensuring reliable performance and minimized defects. The trend toward using complex, lightweight materials continues to shape the demand for cutting-edge injection molding machinery, making it a fundamental part of modern manufacturing strategies.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $10.4 Billion |

| Forecast Value | $16.5 Billion |

| CAGR | 4.8% |

The hydraulic injection molding machines segment reached USD 5.2 billion in 2024 and is expected to grow at a CAGR of 4.8% through 2034. These machines remain favored for producing larger and heavier components due to their reliability and lower initial cost. Although their growth is moderate, they still hold a strong position due to widespread usage. However, electric injection molding machines are gaining traction, offering benefits like improved energy efficiency, higher accuracy, reduced noise levels, and lower maintenance requirements, which appeal to manufacturers focused on sustainability and operational efficiency.

The plastic materials segment held a 32% share in 2024 and is forecast to grow at a CAGR of 4.4% from 2025 to 2034. The continued dominance of plastic is tied to its versatility, ease of molding, and rising demand across applications like consumer goods, packaging, and automotive components. Its lightweight nature and cost-effectiveness make it the go-to choice in industries where product design and mass production play a critical role in profitability.

U.S. Injection Molding Machine Market held a 76% share and generated USD 2.15 billion in 2024. The growth in this region is closely linked to industries such as healthcare, automotive, and packaging that are shifting toward lightweight, precision plastic parts. Companies are increasingly replacing older equipment with modern machines that improve productivity and output quality. The surge in adoption of electric and hybrid machines reflects the expanding role of automation and efficiency in manufacturing across the region.

Key players driving advancements in the Global Injection Molding Machine Industry include Milacron, Haitian International, ENGEL, JSW, KraussMaffei, Yizumi, Fanuc, Nissei Plastic Industrial, Sumitomo, Shibaura Machine, Toyo Machinery & Metal, Wittmann Battenfeld, Arburg, Husky Injection Molding Systems, and Chen Hsong Holdings. These companies are consistently focused on innovation, automation, and system integration. Top companies in the injection molding machine market are focused on adopting smart manufacturing technologies and automation to improve production efficiency. Investment in energy-efficient and all-electric models has grown significantly, meeting increasing demand for sustainable solutions. Firms are continuously expanding their product lines to support complex applications, especially in high-precision sectors like medical devices and electronics. Strategic partnerships and collaborations help companies develop localized solutions for specific regional demands. Key players are also upgrading digital interfaces, integrating IoT, and offering remote monitoring capabilities to provide better machine diagnostics and reduce downtime.