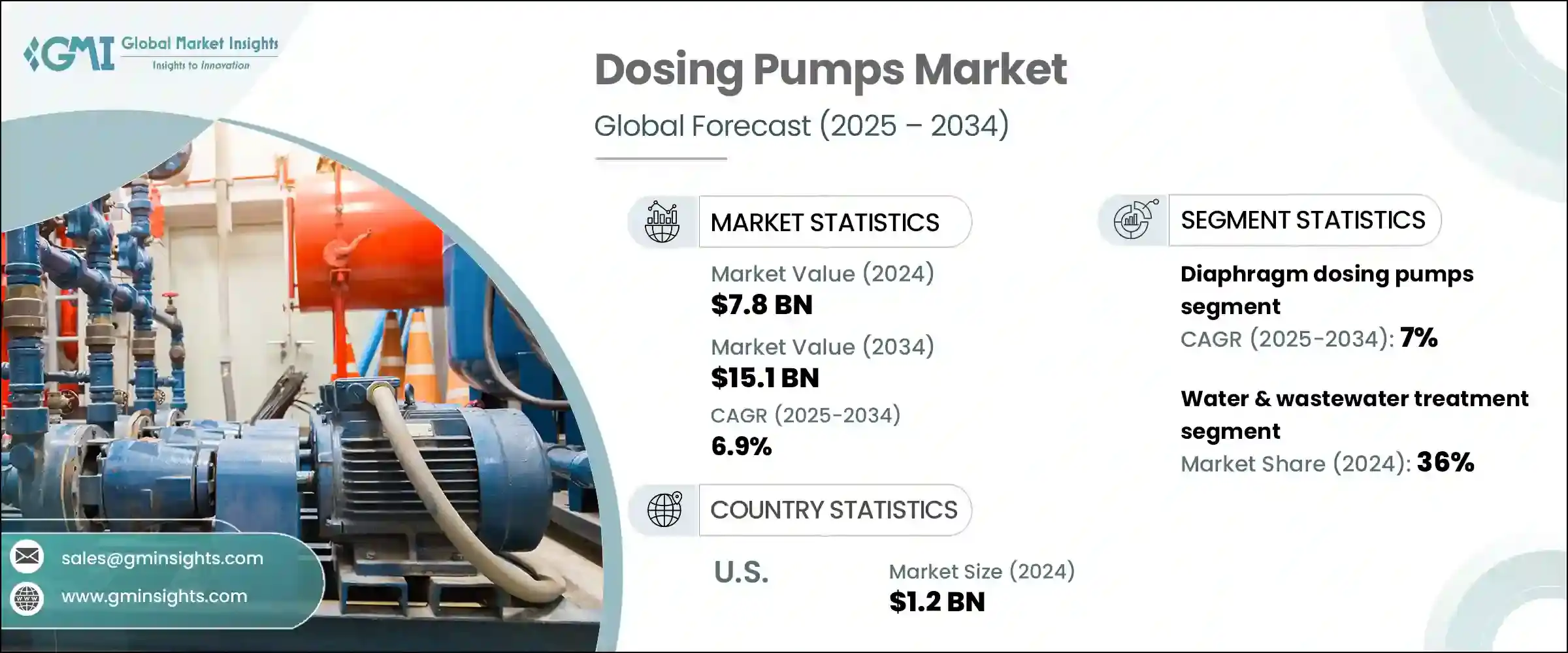

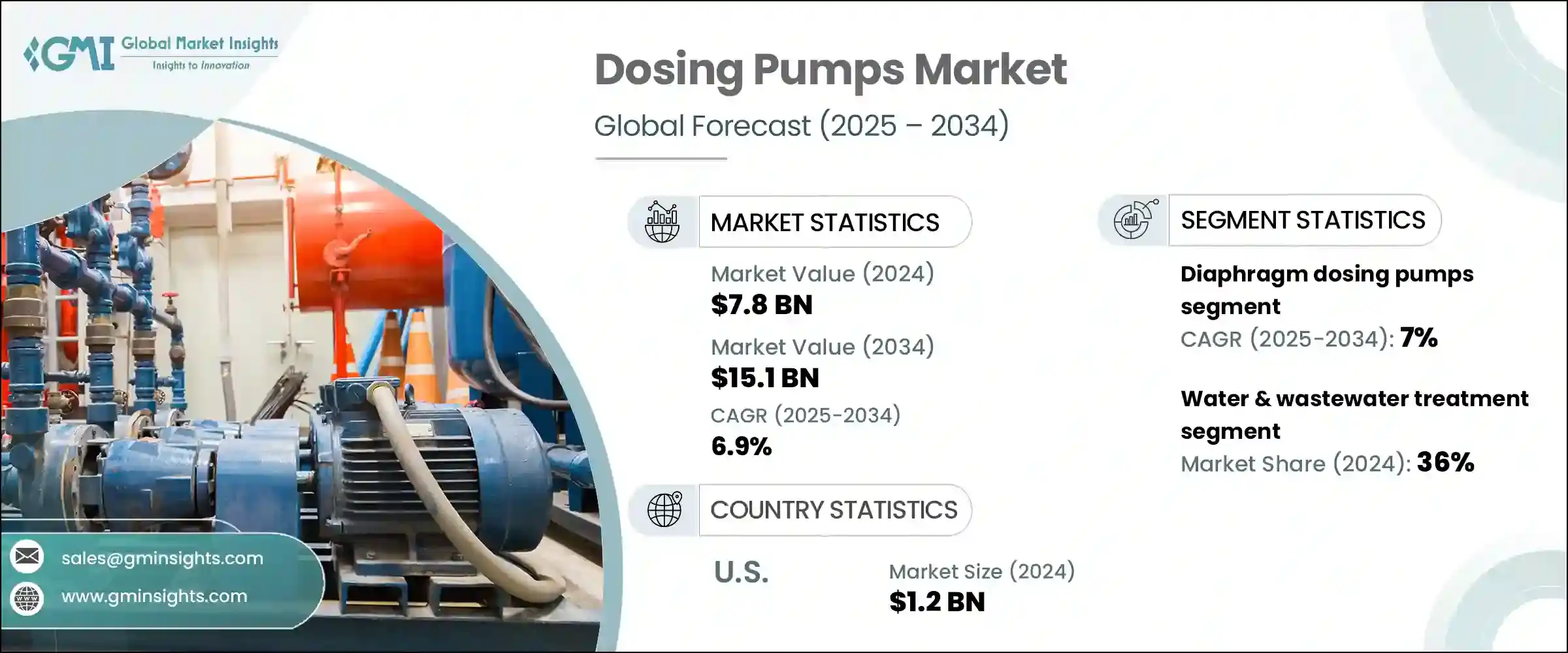

세계의 정량 펌프 시장 규모는 2024년에 78억 달러에 달하며, CAGR 6.9%로 성장하며, 2034년에는 151억 달러에 달할 것으로 예측됩니다.

정확한 투약, 실시간 모니터링, 자동 피드백 제어를 가능하게 하는 디지털 컨트롤러의 통합이 주요 촉진요인입니다. 지자체 및 산업 폐수 시설에서는 염소, 오존, UV 투약 시스템에 대한 의존도가 증가하고 있으며, 도시 지역에서는 국소 정수 장비가 도입되고 있습니다. 식품 및 음료 분야에서는 방부제, 향료, 착색제의 정확한 주입을 위해 정량 펌프가 필수적입니다. 석유 및 가스 산업에서는 부식방지제용 고압 펌프, 플랫폼 및 FPSO용 내염 및 방폭 시스템, 해저 파이프라인의 메탄올 및 글리콜 주입 등에 대한 수요가 증가하고 있습니다. 자동 캘리브레이션과 IoT 기반 원격 연결은 효율성과 예지보전을 더욱 향상시키고 있습니다.

고점도, 부식성, 연마성 화학물질에 대응하도록 설계된 약품 주입 펌프 기술의 끊임없는 혁신은 다양한 산업 분야에서 시장 기회를 크게 확장하고 있습니다. 강화 폴리머 및 내식 합금과 같은 첨단 소재는 열악한 작동 조건에서 내구성과 수명을 향상시키기 위해 현재 펌프 구조에 통합되어 있습니다. 또한 강화된 실링 메커니즘, 가변 속도 드라이브 지원, 정밀한 유량 제어 기능을 통해 이 펌프는 광업, 폐수 처리, 펄프 및 제지, 석유 및 가스 등의 까다로운 용도에서 효율적으로 작동할 수 있습니다. 산업계가 최소한의 다운타임과 유지보수로 복잡한 화학물질 주입 공정을 자동화하고자 하는 가운데, 이러한 견고한 고성능 주입 시스템에 대한 수요는 꾸준히 증가하고 있으며, 이는 성장과 제품 다양화를 위한 새로운 길을 열어주고 있습니다.

| 시장 범위 | |

|---|---|

| 시작연도 | 2024 |

| 예측연도 | 2025-2034 |

| 시작 금액 | 78억 달러 |

| 예측 금액 | 151억 달러 |

| CAGR | 6.9% |

연동 정량 펌프 분야는 위생적인 유체 취급과 무공해 작동을 필요로 하는 산업 분야 수요 증가로 인해 2034년까지 25억 달러에 달할 것으로 예측됩니다. 밀폐된 비침습적 유체 경로는 제품의 순도가 중요한 생명공학, 제약, 식품 제조 등의 분야에 매우 적합합니다. 툴이 필요 없는 편리한 튜브 교체는 유지보수를 단순화할 뿐만 아니라 장비 가동 시간을 최대화하고, 작동 지연을 줄이며, 노동 강도를 최소화합니다. 클린룸 규정 준수와 제품 무결성이 이러한 산업에서 최우선 순위로 떠오르고 있는 가운데, 페리스타 펌프는 교차 오염의 위험을 최소화하고 무균 처리 환경을 보장하는 능력을 통해 계속해서 입지를 다져가고 있습니다.

화학 처리 정량 펌프 분야는 2034년까지 35억 달러에 달할 것으로 예상되며, 이는 제조업체들이 부식성이 강한 액체와 위험한 화학 물질을 처리할 수 있는 내구성 있고 정밀한 시스템을 요구하기 때문입니다. 증기 배출을 최소화하고 직장 안전을 극대화하도록 설계된 폐쇄형 루프 시스템과의 호환성은 화학, 석유화학 및 산업 제조 현장에서 필수적인 요소로 자리 잡고 있습니다. 이 펌프는 생산 효율에 필수적인 중단 없는 약액 주입을 수행하는 대용량 플랜트에서 24시간 365일 연속 사용하도록 구성되는 경우가 많습니다. 극한의 온도와 압력에서도 작동할 수 있는 능력과 자동화에 대한 대응력은 까다로운 용도에서 선호되는 선택이 되고 있습니다.

북미 정량 펌프 2034년까지 북미 시장은 30억 달러에 달할 것으로 예상되며, 인프라 업그레이드와 환경 규정 준수의 강화가 그 원동력이 되고 있습니다. 공공 기관이 노후화된 수처리 인프라를 현대화해야 하는 상황에서 디지털 정량 펌프는 기존의 기계식 시스템을 빠르게 대체하고 있습니다. 디지털 정량 펌프는 염소, 불소 및 기타 처리 약품의 투여 정확도를 높여 진화하는 EPA 표준에 대한 규제 준수를 보장합니다. 유틸리티 및 산업체들은 지속가능성, 비용 절감, 공중 보건 보호라는 광범위한 목표에 따라 원격 모니터링 및 제어 기능을 갖춘 스마트 네트워크 펌프를 우선순위에 두고 있습니다.

세계의 정량 펌프 시장에 관련된 주요 기업은 Ark Electric & Mechanical, Blue White, Dosimix Technologies, Emec, Firemiks, Grundfos Holding, IDEX Corporation, Ingersoll Rand, IWAKI, KNAUER Wissenschaftliche Gerate, NETZSCH, Nikkiso, Phoenix Pumps, ProMinent, PSG, Roto Pumps, SEKO, SPX Flow, Verder Liquids, Verito Engineering, W.E.S.입니다. 각 제조업체들은 스마트 토출 솔루션에 대한 수요를 충족하고 다운타임을 줄이기 위해 IoT 연결, 원격 진단, 자동 교정 기능을 통합한 디지털 혁신에 많은 투자를 하고 있습니다. 또한 까다로운 석유, 가스 및 산업 환경을 위해 내식성, 내열성, 내염성, 내압방폭성 펌프도 개발하고 있습니다. 전략적 성장 전략으로는 엔지니어링 회사 및 지자체 유틸리티과 파트너십을 맺고, 특히 폐수 및 수처리 분야에서 첨단 시스템을 시범적으로 도입하는 것을 들 수 있습니다. 제품 포트폴리오는 식품 및 생명공학의 무균 용도에 적합한 연동 모델로 확장되고 있으며, 폐쇄형 화학 펌프는 안전과 규정 준수를 보장합니다.

The Global Dosing Pumps Market was valued at USD 7.8 billion in 2024 and is estimated to grow at a CAGR of 6.9% to reach USD 15.1 billion by 2034. The integration of digital controllers, which enable precise dosing, real-time monitoring, and automated feedback control, is a key growth driver. Municipal and industrial wastewater facilities increasingly rely on chlorine, ozone, and UV dosing systems, while urban centers deploy local water purification units. In the food and beverage sector, dosing pumps are vital for accurate injection of preservatives, flavorings, and colorants. The oil and gas industry boosts demand for high-pressure pumps for corrosion inhibitors, salt-resistant and explosion-proof systems for platforms and FPSOs, and methanol and glycol injection in subsea pipelines. Auto-calibration and IoT-enabled remote connectivity are further enhancing efficiency and predictive maintenance.

Continuous innovation in dosing pump technology designed to handle highly viscous, corrosive, or abrasive chemicals is significantly expanding market opportunities across various industrial sectors. Advanced materials, such as reinforced polymers and corrosion-resistant alloys, are now being integrated into pump construction to improve durability and lifespan under extreme operating conditions. Additionally, enhanced sealing mechanisms, variable-speed drive compatibility, and precision flow control features enable these pumps to operate efficiently in challenging applications like mining, wastewater treatment, pulp and paper, and oil & gas. As industries seek to automate complex chemical dosing processes with minimal downtime and maintenance, demand for these rugged, high-performance dosing systems is rising steadily, opening new avenues for growth and product diversification.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $7.8 Billion |

| Forecast Value | $15.1 Billion |

| CAGR | 6.9% |

The peristaltic dosing pumps segment is forecasted to reach USD 2.5 billion by 2034, driven by increasing demand from industries requiring hygienic fluid handling and contamination-free operation. Their sealed, non-invasive fluid pathways make them highly suitable for sectors like biotechnology, pharmaceuticals, and food production, where product purity is critical. The convenience of tool-free tubing replacement not only simplifies maintenance but also maximizes equipment uptime, reducing operational delays and minimizing labor intensity. As cleanroom compliance and product integrity remain top priorities in these industries, peristaltic pumps continue to gain ground for their ability to ensure sterile processing environments with minimal risk of cross-contamination.

The chemical processing dosing pumps segment is expected to reach USD 3.5 billion by 2034 as manufacturers seek durable, high-precision systems capable of handling aggressive fluids and hazardous chemicals. Their compatibility with closed-loop systems-designed to minimize vapor emissions and maximize workplace safety-makes them indispensable in chemical, petrochemical, and industrial manufacturing settings. These pumps are increasingly configured for continuous 24/7 use in high-capacity plants, where uninterrupted chemical dosing is vital to production efficiency. Their capacity to operate under extreme temperatures and pressures, coupled with automation readiness, makes them a preferred choice for demanding applications.

North America Dosing Pumps Market is expected to reach USD 3 billion by 2034, propelled by infrastructure upgrades and stricter environmental compliance mandates. As public utilities face mounting pressure to modernize outdated water treatment infrastructure, digital dosing pumps are rapidly replacing traditional mechanical systems. Enhanced precision in dosing chlorine, fluoride, and other treatment chemicals ensures regulatory alignment with evolving EPA standards. Utilities and industrial operators alike are prioritizing smart, networked pumps with remote monitoring and control capabilities, aligning with broader goals of sustainability, cost reduction, and public health protection.

Key players involved in the Global Dosing Pumps Market are Ark Electric & Mechanical, Blue White, Dosimix Technologies, Emec, Firemiks, Grundfos Holding, IDEX Corporation, Ingersoll Rand, IWAKI, KNAUER Wissenschaftliche Gerate, NETZSCH, Nikkiso, Phoenix Pumps, ProMinent, PSG, Roto Pumps, SEKO, SPX Flow, Verder Liquids, Verito Engineering, W.E.S. Manufacturers are investing heavily in digital innovation-integrating IoT connectivity, remote diagnostics, and auto-calibration features to meet demand for smart dosing solutions and reduce downtime. They are also developing corrosion-, heat-, salt-, and explosion-resistant pumps for demanding oil, gas, and industrial environments. Strategic growth tactics include forming partnerships with engineering firms and municipal utilities to pilot advanced systems, especially in wastewater and water treatment. Product portfolios are being expanded with peristaltic models tailored for food and biotech sterile applications, while closed-system chemical pumps ensure safety and compliance.