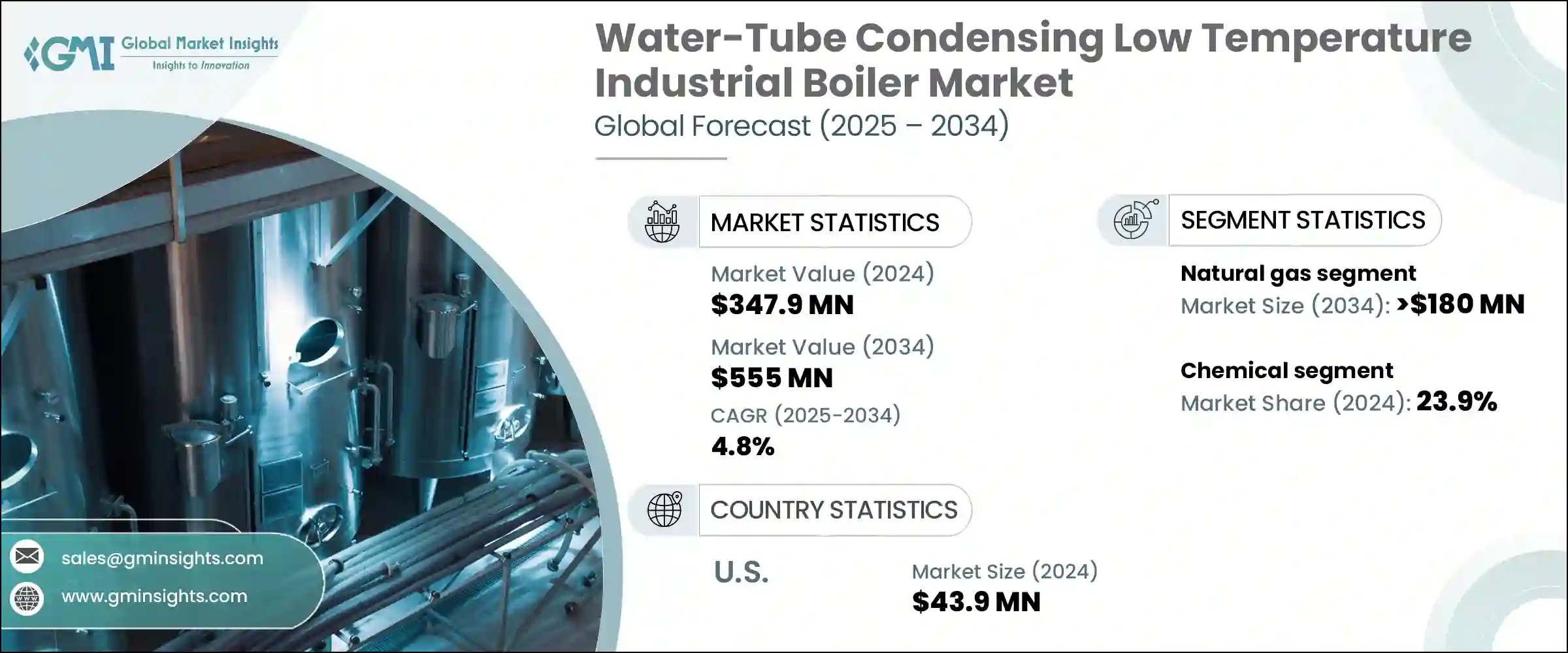

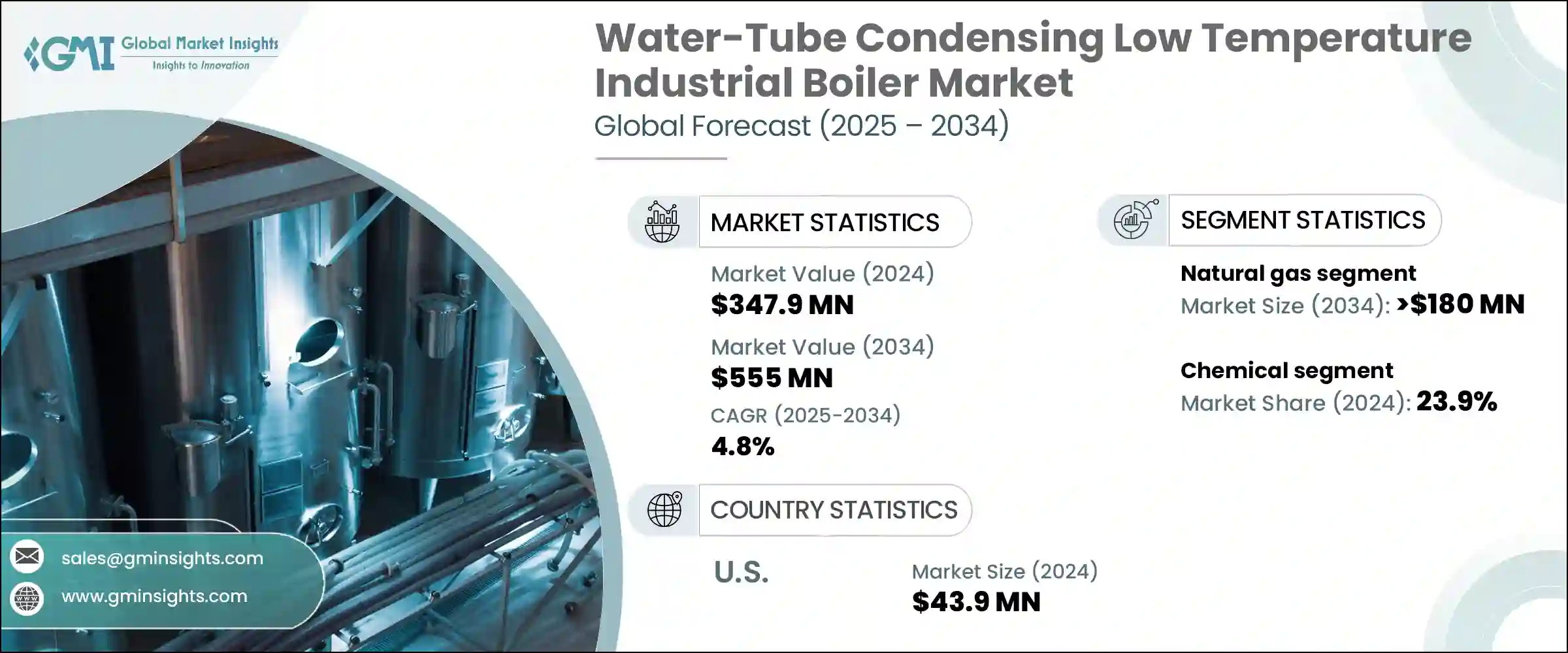

세계의 산업용 수관식 저온 컨덴싱 보일러 시장은 2024년에는 3억 4,790만 달러에 달하였고, CAGR 4.8%로 성장하여 2034년에는 5억 5,500만 달러에 이를 것으로 예측되고 있습니다.

이 꾸준한 확대는 시대에 뒤떨어진 산업 시스템의 현대화와 스마트 보일러 기술의 채용 가속화에 의해 발생하고 있습니다. 식음료와 같은 분야에서 수요 증가와 기동 시간이 짧은 에너지 절약 시스템에 대한 요구가 지능적이고 지속 가능한 가열 솔루션으로의 폭넓은 전환을 뒷받침하고 있습니다.

환경 규제가 강화되고 산업계가 지속 가능성을 중시하게 됨에 따라 에너지 성능과 배출량 감축을 양립시킨 보일러에 대한 수요가 높아질 것으로 예측됩니다. 또한 금속 및 식품 제조와 같은 제조 환경에서의 정밀한 열 제어의 요구가 양호한 성장 궤도를 형성하고 있습니다.

| 시장 범위 | |

|---|---|

| 시작연도 | 2024 |

| 예측연도 | 2025-2034 |

| 시작금액 | 3억 4,790만 달러 |

| 예측금액 | 5억 5,500만 달러 |

| CAGR | 4.8% |

산업용 수관식 저온 컨덴싱 보일러 시장의 천연가스 부문은 2034년까지 1억 8,000만 달러에 달할 것으로 예측되고 있습니다. 산업 환경을 위한 일관된 온도 제어에 의존하는 산업에서는 에너지 효율과 변동 부하 조건 하에서의 신뢰성으로 인해 이러한 천연가스 보일러가 그 요구에 특히 적합합니다.

종이 및 펄프 분야의 산업용 수관식 저온 컨덴싱 보일러 시장은 2034년까지 연평균 복합 성장률(CAGR) 4.9%를 보일 것으로 예측됩니다. 이 유닛에는 고급 안전기술, 지능형 모니터링 기능, 자동 종료 기능이 탑재되어 있으며, 이들 모두가 성능의 일관성과 안전성을 향상시키면서 안전기준 준수를 보장하고 있습니다.

미국의 산업용 수관식 저온 컨덴싱 보일러 시장은 2024년에 4,390만 달러로 평가되었습니다.

경쟁구도는 Cleaver-Brooks, Babcock Wanson, EPCB Boiler, Miura America, Fulton, Victory Energy Operations, Clayton Industries, Rentech Boilers, Johnston Boiler, IHI Corporation, Burnham Commercial Boilers, Hurst Boiler Boilers, Thermax, Babcock & Wilcox와 같은 대기업들로 이루어집니다.

시장의 발판을 굳히기 위해 산업용 수관식 저온 컨덴싱 보일러 분야의 주요 기업은 기술 혁신, 지속 가능성, 세계 시장 전개에 주력하고 있습니다. 많은 기업들이 스마트 제어 기술을 채택하고 실시간 모니터링과 예측 유지보수를 실현하여 다운타임과 운전 비용을 최소화하고 있습니다.

The Global Water-Tube Condensing Low Temperature Industrial Boiler Market was valued at USD 347.9 million in 2024 and is estimated to grow at a CAGR of 4.8% to reach USD 555 million by 2034. This steady expansion is largely driven by the modernization of outdated industrial systems and the accelerating adoption of smart boiler technologies. Growing investment in high-efficiency designs and the implementation of corrosion-resistant, long-lasting components are further encouraging market growth. Increasing demand from sectors such as food and beverage, coupled with the need for energy-saving systems with fast startup times, is supporting a broader shift toward intelligent and sustainable heating solutions.

As environmental regulations tighten and industrial operations emphasize sustainability, the demand for boilers that combine energy performance with reduced emissions is expected to rise. These systems enhance fuel efficiency and align with global energy efficiency targets. Evolving industrial needs, particularly for precise thermal control in manufacturing environments like primary metals and food production, are shaping a favorable growth trajectory. The integration of predictive analytics, modular designs, and smart controls is expected to transform reliability, fuel use, and operational stability across industries based on accurate and consistent heat delivery.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $347.9 Million |

| Forecast Value | $555 Million |

| CAGR | 4.8% |

The natural gas segment in the water-tube condensing low temperature industrial boiler market is projected to reach USD 180 million by 2034. These systems are for high-demand industrial settings where maintaining temperature precision directly influences product quality and operational throughput. Industries that depend on consistent thermal control are finding these natural gas boilers especially suited to their needs, thanks to both their energy efficiency and reliability under variable load conditions.

The water-tube condensing low temperature industrial boiler market in the pulp & paper segment is forecasted to grow at a CAGR of 4.9% through 2034. These units are equipped with advanced safety technologies, intelligent monitoring capabilities, and automated shutdown features, all of which ensure compliance with safety standards while improving performance consistency and risk mitigation. This focus on performance and safety is encouraging adoption across industrial applications that rely on uninterrupted thermal processes.

United States Water-Tube Condensing Low-Temperature Industrial Boiler Market was valued at USD 43.9 million in 2024. With growing emphasis on reducing emissions and improving energy efficiency, businesses across the country are increasingly turning to these advanced boiler systems. The shift toward greener technologies and thermal management supports market growth in the US.

The competitive landscape includes major companies such as Cleaver-Brooks, Babcock Wanson, EPCB Boiler, Miura America, Fulton, Victory Energy Operations, Clayton Industries, Rentech Boilers, Johnston Boiler, IHI Corporation, Burnham Commercial Boilers, Hurst Boiler & Welding, Thermodyne Boilers, Thermax, and Babcock & Wilcox.

To strengthen their market foothold, key players in the water-tube condensing low-temperature industrial boiler sector are focusing on innovation, sustainability, and global expansion. Companies are heavily investing in R&D to develop next-gen boilers with better heat recovery, lower emissions, and enhanced fuel flexibility. Many companies adopt smart control technologies, allowing real-time monitoring and predictive maintenance, minimizing downtime and operational costs. Strategic partnerships and acquisitions are also being used to expand product portfolios and enhance service networks.