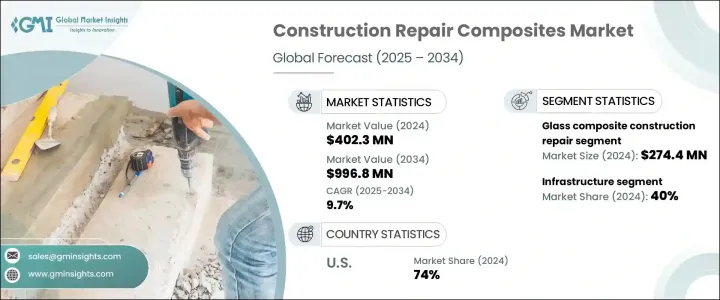

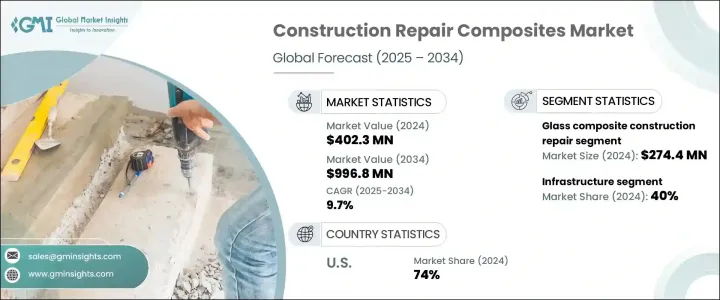

세계의 건설 수리 복합재 시장은 2024년에 4억 230만 달러로 평가되었고 세계 건설 동향을 형성하는 몇 가지 중요한 요인에 의해 2034년에는 9억 9,680만 달러에 이를 것으로 예측되며, CAGR 9.7%로 성장할 전망입니다.

지속 가능한 건설 자재에 대한 투자 증가, 복합재 제조 기술 발전, 노후화된 인프라를 재건하려는 노력 증가로 인해 시장은 강력한 모멘텀을 목격하고 있습니다. 도시 개발이 가속화되고 지속가능성이 최우선 과제로 떠오르면서 복합 소재는 건축 환경의 수리 분야에 선호되는 솔루션으로 부상하고 있습니다.

내구성이 뛰어나고 비용 효율적인 솔루션에 대한 요구가 증가함에 따라 복합재는 기존 건축 자재에 대한 가치 있는 대안으로 자리매김하고 있습니다. 강도, 내식성, 수명 측면에서 뛰어난 성능을 자랑하는 복합재는 건설 산업 전반에서 점점 더 인정받고 있습니다. 인프라가 노후화된 많은 지역에서 노후화된 구조물을 보수하고 보강하기 위해 복합 소재를 사용하는 방향으로 전환하고 있습니다. 개발도상국의 급속한 도시 확장은 새로운 인프라를 건설할 뿐만 아니라 기존 인프라를 업그레이드해야 한다는 압박을 유발하기 때문에 시장 수요에 기여하고 있습니다. 또한 스마트 시티 개발로의 전환으로 인해 첨단 소재가 우선순위가 되었으며, 복합재는 장기 유지보수 비용을 줄이고 지속 가능성을 개선하기 위한 현대식 수리 분야에서 중요한 역할을 하고 있습니다. 공공 인프라 리뉴얼에 대한 정부의 투자는 특히 까다로운 환경 조건에서 장기적인 성능이 요구되는 부문에서 복합재 채택을 더욱 촉진하고 있습니다.

| 시장 범위 | |

|---|---|

| 시작 연도 | 2024년 |

| 예측 연도 | 2025-2034년 |

| 시작 금액 | 4억230만 달러 |

| 예측 금액 | 9억 9,680만 달러 |

| CAGR | 9.7% |

섬유 유형별로 건설 수리 복합재 시장은 탄소 섬유, 유리 섬유 및 기타로 분류됩니다. 2024년 유리 섬유 부문은 2억 7,440만 달러의 매출을 기록하며 시장을 지배했으며, 2034년까지 약 9.9%의 CAGR로 성장할 것으로 예상됩니다. 유리 섬유 복합재는 경제성, 내구성, 기계적 강도의 조합을 제공하기 때문에 계속해서 주목을 받고 있습니다. 이러한 복합재는 일반적으로 다양한 건축 구성 요소를 보강하고 수리하는 데 사용되며, 기존 옵션에 비해 서비스 수명을 연장하고 유지보수를 줄일 수 있습니다.

유리 섬유 복합재는 보, 기둥, 기초와 같은 구조 요소를 수리하는 데 널리 적용되며, 그 강도와 탄력성이 실질적인 이점을 제공합니다. 수지 주입 및 인발 성형 등 제조 기술의 발전으로 이러한 소재의 구조적 성능이 향상되어 다양한 건설 수리 요구 사항에 더욱 안정적이고 적응력이 높아졌습니다. 또한 가벼운 특성 덕분에 설치가 간편해져 인건비와 프로젝트 기간이 단축됩니다. 따라서 유리 섬유는 특히 구조적 무결성과 장기적인 내구성이 중요한 상업용 및 주거용 수리 분야에서 매력적인 선택이 될 수 있습니다.

건설 수리 복합재 시장은 용도별로 주거용 건물, 상업용 건물, 산업 시설 및 인프라로 나뉩니다. 이 중 인프라 부문은 2024년에 약 40%의 상당한 점유율을 차지할 것으로 예상됩니다. 중요 인프라의 수리 및 강화가 이 부문에서 복합재 채택의 주요 촉진요인입니다. 복합 소재는 구조적 복원력을 높이고 노후화된 시스템의 운영 수명을 연장하기 위해 보수 프로젝트에 점점 더 많이 통합되고 있습니다.

인프라 네트워크가 성숙한 지역에서는 오래된 구조물의 무결성을 손상시키지 않으면서 복구해야 할 필요성으로 인해 고성능 복합재의 사용이 증가하고 있습니다. 특히 탄소섬유 복합재는 높은 인장 강도와 최소한의 무게가 요구되는 프로젝트에서 수요가 증가하고 있습니다. 이러한 특성 덕분에 구조적으로 효율적이면서 상당한 하중을 견뎌야 하는 부품을 보강하는 데 이상적입니다. 또한 비부식성 특성 덕분에 습기나 화학물질에 노출되는 환경에도 적합합니다.

북미는 건설 수리 복합재 시장을 선도하는 지역으로, 미국은 2024년 지역 시장 점유율의 약 74%를 차지하며 약 1억 300만 달러의 수익을 창출할 것으로 예상됩니다. 미국 시장은 재활과 지속 가능성에 초점을 맞춘 정책 이니셔티브를 통해 인프라 현대화에 대한 연방 정부의 강력한 지원의 혜택을 받고 있습니다. 인프라 활성화를 위한 입법적 노력은 강도와 내구성을 모두 갖춘 첨단 수리 재료에 대한 수요 증가로 이어지고 있습니다.

복합재는 인프라 리뉴얼의 기술적 요구 사항을 충족하는 동시에 환경 목표에 부합하는 능력으로 인해 채택되고 있습니다. 교통망에서 공공시설에 이르기까지 다운타임을 최소화하고 구조물 수명을 연장하는 솔루션에 대한 선호도가 높아지고 있습니다. 이러한 선호도 증가는 전국적으로 섬유 강화 복합재의 혁신과 광범위한 채택을 촉진하고 있습니다.

세계 건설 수리 복합재 시장에서 사업을 전개하는 주요 기업으로는 Chomarat, BASF, Creative Composites, Dow, Fosroc, Dextra, Henkel, Mapei, Owens Corning, Rockwool, Master Builders Solutions, Saint-Gobain, Simpson Strong-Tie, Sika, Sireg Geotech 등이 있습니다. 이 기업들은 점점 더 경쟁이 치열해지고 품질 중심이 되는 시장에서 입지를 강화하기 위해 소재 혁신, 제품 라인 확장, 전략적 파트너십 구축에 집중하고 있습니다.

The Global Construction Repair Composites Market was valued at USD 402.3 million in 2024 and is estimated to grow at a CAGR of 9.7% to reach USD 996.8 million by 2034, driven by several key factors shaping global construction trends. The market is witnessing strong momentum due to growing investments in sustainable construction materials, technological progress in composite manufacturing, and increasing efforts to rehabilitate aging infrastructure. As urban development accelerates and sustainability becomes a top priority, composite materials are emerging as a preferred solution for repair applications in the built environment.

The rising need for durable and cost-efficient solutions has positioned composites as a valuable alternative to traditional construction materials. Their superior performance in terms of strength, corrosion resistance, and longevity is increasingly recognized across the construction industry. In many regions with aging infrastructure, there is a clear shift toward the use of composite materials to repair and reinforce deteriorating structures. Rapid urban expansion in developing countries also contributes to market demand, as it creates pressure to not only build new infrastructure but also upgrade existing ones. Additionally, the shift toward smart city development has made advanced materials a priority, with composites playing a vital role in modern repair applications aimed at reducing long-term maintenance costs and improving sustainability. Government investments in public infrastructure renewal are further fueling the adoption of composites, especially in sectors that require long-term performance under challenging environmental conditions.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $402.3 Million |

| Forecast Value | $996.8 Million |

| CAGR | 9.7% |

By fiber type, the construction repair composites market is segmented into carbon fiber, glass fiber, and others. In 2024, the glass fiber segment dominated the market, accounting for USD 274.4 million in revenue, and is projected to grow at a CAGR of around 9.9% through 2034. Glass fiber composites continue to gain traction because they offer a combination of affordability, durability, and mechanical strength. These composites are commonly used to reinforce and repair a wide range of construction components, providing extended service life and reduced maintenance compared to conventional options.

Glass fiber composites are widely applied in repairing structural elements such as beams, columns, and foundations, where their strength and resilience offer a practical advantage. Advancements in fabrication techniques, including resin infusion and pultrusion, have improved the structural performance of these materials, making them more reliable and adaptable to diverse construction repair needs. Their lightweight nature also simplifies installation, cutting down labor costs and project timeframes. This makes glass fiber a compelling choice for both commercial and residential repair applications, particularly when structural integrity and long-term durability are critical.

In terms of application, the construction repair composites market is divided into residential buildings, commercial buildings, industrial facilities, and infrastructure. Among these, the infrastructure segment held a substantial share of around 40% in 2024. Repair and strengthening of critical infrastructure are primary drivers of composite adoption in this category. Composite materials are increasingly integrated into repair projects to enhance structural resilience and extend the operational lifespan of aging systems.

In regions with mature infrastructure networks, the need to rehabilitate old structures without compromising their integrity is pushing the use of high-performance composites. Carbon fiber composites, in particular, are experiencing rising demand in projects requiring high tensile strength and minimal weight. These characteristics make them ideal for reinforcing components that must bear substantial loads while remaining structurally efficient. Their non-corrosive properties also make them suitable for environments where exposure to moisture or chemicals is common.

North America remains a leading region in the construction repair composites market, with the United States accounting for roughly 74% of the regional market share in 2024 and generating about USD 103 million in revenue. The U.S. market is benefiting from strong federal support for infrastructure modernization through policy initiatives focused on rehabilitation and sustainability. Legislative efforts aimed at infrastructure revitalization are translating into heightened demand for advanced repair materials that deliver both strength and durability.

Composite materials are being embraced for their ability to meet the technical requirements of infrastructure renewal while also aligning with environmental goals. From transportation networks to public utilities, there is a growing preference for solutions that minimize downtime and extend structure lifespans. This growing preference is fueling innovation and wider adoption of fiber-reinforced composites across the country.

Key players operating in the global construction repair composites market include Chomarat, BASF, Creative Composites, Dow, Fosroc, Dextra, Henkel, Mapei, Owens Corning, Rockwool, Master Builders Solutions, Saint-Gobain, Simpson Strong-Tie, Sika, and Sireg Geotech. These companies are focusing on material innovation, expanding product lines, and forging strategic partnerships to strengthen their position in a market that is becoming increasingly competitive and quality-driven.