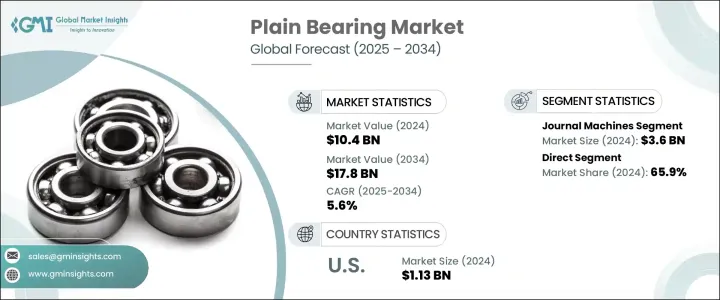

플레인 베어링 세계 시장 규모는 2024년에 104억 달러로 평가되었고, CAGR 5.6%로, 2034년에는 178억 달러에 이를 것으로 추정됩니다.

이 일관된 성장의 원동력은 고성능 기계에서의 자동화의 보급입니다. 따라서 점점 더 중요해지고 있습니다. 이 부품은 내구성과 높은 하중을 견딜 수있는 능력으로 인해 기계가 가혹한 조건이나 오염된 조건에서 작동해야하는 응용 분야에서 특히 평가됩니다.

생산 라인에서 물류, 자재관리에 이르기까지 다양한 분야에서 자동화가 진행되고 있는 것이 플레인 베어링 수요를 지지하고 있습니다. 감소와 가동 시간의 극대화에 기여하고 있습니다. 시장은 경량이고 내구성이 있어, 유지관리 프리의 부품이 불가결한 항공우주 분야의 확대도 뒷받침하고 있습니다.

| 시장 범위 | |

|---|---|

| 시작 연도 | 2024년 |

| 예측 연도 | 2025-2034년 |

| 시작 금액 | 104억 달러 |

| 예측 금액 | 178억 달러 |

| CAGR | 5.6% |

제품 유형별로 플레인 베어링은 앵귤러 접점, 저널, 선형, 스러스트 및 기타 유형으로 구분됩니다. 저널 베어링이 가장 큰 비중을 차지하여 2024년에 36억 달러의 매출을 올렸습니다. 이 부문은 2025년부터 2034년에 걸쳐 약 6.2%의 연평균 복합 성장률(CAGR)로 성장할 것으로 예측되고 있습니다. 저널 베어링은 단순한 디자인과 고속 고부하 애플리케이션을 지원하는 능력으로 선호됩니다. 윤활과 연속 회전 운동을 촉진하는 플레인 베어링의 능력은 마찰을 최소화하고, 궁극적으로 유지 보수 비용을 줄이고, 생산성에 의존하는 분야에서 중요한 요소인 장비의 수명을 향상시킵니다.

시장에서 플레인 베어링의 유통은 직접 채널과 간접 채널로 분류됩니다. 직접 판매는 부품의 신뢰성과 기술 통합의 정밀도를 양도할 수 없는 항공우주, 자동차, 중기 등의 정밀도가 요구되는 산업에서 특히 중요합니다. 성능에 대한 우려에 의해 효율적으로 대응하고, 리얼타임 피드백을 수집하고, 그에 따라 제품을 적합시킬 수 있기 때문에 고객 만족도가 향상하고, 개발 사이클의 지연을 줄일 수 있습니다.

최종 이용 산업별로는 자동차, 산업, 항공우주, 에너지, 건설기계, 농업, 유전기계, 기타 등의 부문이 있습니다. 자동차를 요구하는 움직임이 강해져 내구성이 높고 경량인 재료에 대한 수요가 높아지고 있어 신뢰성이 높은 베어링 부품의 필요성이 간접적으로 높아지고 있습니다.

북미 시장, 특히 미국은 지속적으로 큰 공헌을 하고 있습니다. 예측 기간 동안 연평균 약 5.7%로 성장할 것으로 예측됩니다. 이 나라에서는 자동차, 항공우주, 산업 자동화 분야에 대한 투자가 증가하고 있으며, 정부의 이니셔티브와 복합재료의 진보 모두에 지지되고 있습니다.

기술 혁신과 시장 확대를 추진하는 주요 기업은 ElringKlinger AG, ELCEE Group, HepcoMotion, NSK Ltd., igus GmbH, NTN Corporation, RBC Bearings, Ovako, Schaeffler Group, SKF Group, SGL Carbon, THK, UBC Precision Bearing Manufacturing, Timken Company &Co.KG입니다. 이들 기업의 대부분은 보다 지속 가능한 관행을 제조 공정에 통합하는 것에 적극적으로 임하고 있습니다. 14001 및 RoHS와 같은 국제 표준을 준수하도록 설계되었습니다. 이 표준은 라이프 사이클 추적, 지속 가능한 물류 및보다 환경 친화적인 제품 설계를 지원하며 이제 플레인 베어링 섹터 전체의 혁신 전략에 필수적입니다.

The Global Plain Bearing Market was valued at USD 10.4 billion in 2024 and is estimated to grow at a CAGR of 5.6% to reach USD 17.8 billion by 2034. This consistent growth is driven by the widespread adoption of automation in high-performance machinery. As industries move toward greater operational precision and productivity, plain bearings are becoming increasingly essential due to their low maintenance requirements and long-term reliability. These components are particularly valued in applications where machinery must perform under harsh or contaminated conditions, thanks to their durability and ability to endure high loads.

The rising integration of automation across sectors-ranging from production lines to logistics and material handling-continues to support the demand for plain bearings. These bearings are often utilized in environments requiring both efficiency and minimal intervention, contributing to cost reductions and maximizing uptime. The market is also experiencing a boost from the expanding aerospace sector, where the need for lightweight, durable, and maintenance-free components is essential. The development and deployment of modern aircraft, along with a rise in international air travel and defense operations, are further amplifying demand.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $10.4 Billion |

| Forecast Value | $17.8 Billion |

| CAGR | 5.6% |

In terms of product type, plain bearings are segmented into angular contact, journal, linear, thrust, and other types. Among these, journal bearings accounted for the largest share, generating USD 3.6 billion in revenue in 2024. This segment is projected to grow at a CAGR of around 6.2% from 2025 to 2034. Journal bearings are favored for their simple design and their capability to support high-speed, high-load applications. Their wide use in engines, turbines, electric motors, pumps, and industrial machinery is tied to their performance reliability, especially in demanding operational environments. Their ability to facilitate continuous rotational movement with appropriate lubrication helps minimize friction, ultimately reducing maintenance expenses and enhancing equipment longevity-factors critical in productivity-dependent sectors.

The distribution of plain bearings in the market is categorized into direct and indirect channels. The direct distribution segment held 65.9% of the market in 2024 and is forecasted to grow at a CAGR of approximately 5.8% throughout the forecast period. Direct sales are particularly important in precision-sensitive industries such as aerospace, automotive, and heavy machinery, where the reliability of parts and the accuracy of technical integration are non-negotiable. Having direct access to customers also enables suppliers to respond more efficiently to performance concerns, gather real-time feedback, and adapt products accordingly, enhancing customer satisfaction and reducing delays in development cycles. Moreover, bypassing intermediaries helps suppliers manage pricing, margins, and inventory more effectively, providing a competitive edge in a market where operational efficiency and product uniqueness are key.

Based on end-use industry, the market includes segments such as automotive, industrial, aerospace, energy, construction equipment, agriculture, oilfield machinery, office products, and others. The automotive sector led the market in 2024 and is expected to retain its dominant position throughout the forecast period. The growing push toward fuel-efficient, high-performance vehicles is increasing the demand for durable and lightweight materials, indirectly fueling the need for reliable bearing components. Technological advancements in automotive manufacturing processes are also creating opportunities for more specialized bearing applications.

The North American market, particularly in the United States, continues to be a major contributor. In 2024, the U.S. plain bearing market was valued at USD 1.13 billion and is projected to grow at a CAGR of 5.7% between 2025 and 2034. The country is seeing increased investments in automotive, aerospace, and industrial automation sectors, supported by both government initiatives and advancements in composite materials. Trends such as reshoring of manufacturing and capital investment in high-tech machinery are also playing a significant role in strengthening the local market.

Key companies driving innovation and market expansion include ElringKlinger AG, ELCEE Group, HepcoMotion, NSK Ltd., igus GmbH, NTN Corporation, RBC Bearings, Ovako, Schaeffler Group, SKF Group, SGL Carbon, THK, UBC Precision Bearing Manufacturing, Timken Company, and ZOLLERN GmbH & Co. KG. Many of these players are actively working to integrate more sustainable practices into their manufacturing processes. This includes reducing friction loss with dry lubrication systems, eliminating lead-based alloys, and adopting eco-friendly casting techniques. As environmental concerns become more pressing, companies are also adhering to international standards such as ISO 14001 and RoHS. These standards support lifecycle tracking, sustainable logistics, and greener product design, which are now integral to innovation strategies across the plain bearing sector.