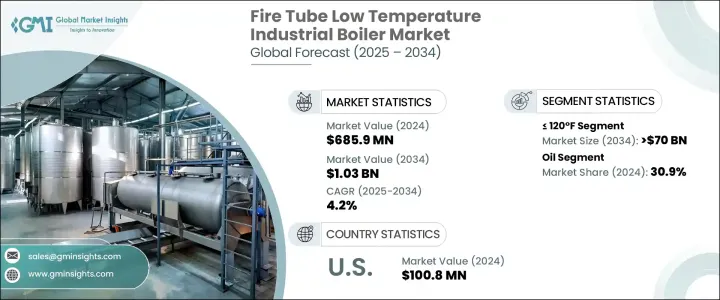

세계의 화관식 저온 산업용 보일러 시장은 2024년에는 6억 8,590만 달러가 되고, CAGR 4.2%로 성장하여 2034년까지는 10억 3,000만 달러에 이를 것으로 예측되고 있습니다.

이 증가 추세는 산업 근대화, 환경 규제 강화, 에너지 효율이 높고 저배출 난방 기술에 대한 수요 증가로 인한 보다 광범위한 산업의 변화를 반영하고 있습니다. 새로운 에너지 기준과 환경 규제에 적합한 선진적인 저온 보일러로의 이행을 뒷받침하고 있습니다.

시장 관계자들 사이에서는 식품 가공, 제약, 화학 등 가열 환경의 제어에 의존하는 섹터로부터의 관심이 높아지고 있습니다. 연소 제어와 열전달 효율의 기술적 진보는 제조업체가 보다 우수한 시스템 통합을 달성하고 규제 준수를 유지하면서 뛰어난 생산성을 높이는데 도움이 됩니다.

| 시장 범위 | |

|---|---|

| 시작 연도 | 2024년 |

| 예측 연도 | 2025-2034년 |

| 시작 금액 | 6억 8,590만 달러 |

| 예측 금액 | 10억 3,000만 달러 |

| CAGR | 4.2% |

다양한 산업 업무에서 에너지 효율이 높고 저출력 가열 솔루션에 대한 수요가 급증하고 있음을 배경으로 큰 성장이 예상되고 있습니다. 또한 저 배출 가스 보일러를 제창하는 엄격한 환경 지령은 이산화탄소 배출량을 삭감하는 정부의 장려책과 함께 저온 산업용 보일러 수요를 더욱 증대시킬 것으로 보입니다.

120°F 이하의 화관식 저온 산업용 보일러 시장은 다양한 산업용 분야에서 효율적인 저온 가열 시스템에 대한 수요가 증가함에 따라 2034년까지 7,000만 달러를 창출할 것으로 예측됩니다. 예를 들어 식품 가공에서 저온 보일러는 제품의 무결성과 맛을 손상시키지 않고 균일하게 가열하는 데 필수적입니다.

화관식 저온 산업용 보일러 시장은 연료 유형에 따라 천연가스, 석유, 기타 대체연료로 분류됩니다. 이러한 지역의 식품 제조업체는 특히 살균, 건조, 저온 살균을 위해 고온 증기를 필요로 하는 프로세스 등, 특정의 업무 요구를 충족시키기 위해서 석유를 동력으로 하는 시스템에 의지하는 경우가 많습니다.

미국의 화관식 저온 산업용 보일러 시장은 2024년에 1억 80만 달러로 평가되었습니다. 이 전환은 지속가능성 중시 증가와 산업용 가열 공정에의 태양광이나 풍력 등의 재생 가능 에너지원의 통합에 의해 추진되고 있습니다. 보다 친환경 기술로의 이행은 산업계가 보다 엄격한 환경 규제를 준수하고, 이산화탄소 배출량을 삭감하려고 하는 가운데, 점점 중요해지고 있습니다.

화관식 저온산업용 보일러 업계에서 사업을 전개하는 주요 기업으로는 Thermodyne Boilers Babcock Wanson, Victory Energy Operations, Hurst Boiler & Welding, Miura America, Babcock & Wilcox, Cleaver-Brooks, ThermexClay, Industries, IHI Corporation, Johnston Boiler, Rentech Boilers, Fulton, EPCB Boiler, Cleaver-Brooks 등이 있습니다. 화관식 저온 산업용 보일러 시장에서의 지위를 강화하기 위해 각 회사는 몇 가지 중요한 전략을 채택하고 있습니다. 대부분은 보일러의 효율과 지속가능성을 향상시키기 위한 기술적 진보에 주력하고 있으며, 이는 향상된 열교환 시스템, 첨단 버너 기술 및 더 나은 에너지 관리를 위한 통합 스마트 제어 기능을 갖춘 보일러 개발을 포함합니다.

The Global Fire Tube Low Temperature Industrial Boiler Market was valued at USD 685.9 million in 2024 and is estimated to grow at a CAGR of 4.2% to reach USD 1.03 billion by 2034. This upward trend reflects a broader industry transformation driven by industrial modernization, stricter environmental regulations, and increasing demand for energy-efficient, low-emission heating technologies. Industries across the globe are under growing pressure to adopt sustainable operations and reduce their carbon footprint, pushing them to transition toward advanced, low-temperature boilers that align with new energy codes and environmental mandates. In emerging economies, aging industrial infrastructure is creating urgent demand for upgraded heating systems, while developed nations are actively replacing outdated units with high-performance alternatives.

Market players are seeing increased interest from sectors that rely on controlled heating environments, such as food processing, pharmaceuticals, and chemicals. These industries are prioritizing heating systems that support consistent temperature management without compromising product quality. Investments in R&D are on the rise, with companies introducing corrosion-resistant materials, smart sensors, and efficient burner systems that enhance reliability and minimize operational costs. Technological advancements in combustion control and heat transfer efficiency are helping manufacturers achieve better system integration, boosting operational productivity while maintaining regulatory compliance. The shift toward clean fuel usage and renewable integration is further opening doors for innovation and market expansion.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $685.9 Million |

| Forecast Value | $1.03 Billion |

| CAGR | 4.2% |

Significant growth is on the horizon, driven by the surging demand for energy-efficient and low-emission heating solutions across various industrial operations. The food processing sector's need for precise and consistent temperatures, combined with heightened investments in product design and adherence to energy efficiency standards, will bolster the industry's landscape. Moreover, stringent environmental mandates advocating for low-emission boilers, alongside government incentives to reduce carbon footprints, will further amplify the demand for low-temperature industrial boilers.

The <= 120°F fire tube low temperature industrial boiler market is anticipated to generate USD 70 million by 2034, driven by the increasing demand for efficient, low-temperature heating systems in various industrial applications. These boilers are commonly used in industries where precise temperature regulation is critical for maintaining product quality, particularly in sectors like food processing, pharmaceuticals, and chemicals. In food processing, for example, low-temperature boilers are essential to ensure that products are heated evenly without compromising their integrity or taste. This type of boiler is ideal for processes like pasteurization, drying, and sterilization, where the temperature needs to be carefully controlled to avoid damage to sensitive materials.

The fire tube low-temperature industrial boiler market is categorized based on fuel type into natural gas, oil, coal, and other alternatives. Among these, the oil-fired segment held a 30.9% share in 2024. In particular, oil-based boilers are essential in remote areas where access to other fuel sources may be limited or impractical. Food manufacturers in such regions often rely on oil-powered systems to meet their specific operational needs, particularly for processes that require high-temperature steam for sterilization, drying, and pasteurization. Oil-fired boilers are favored in these settings due to their ability to provide reliable and consistent heat output, which is crucial for ensuring the quality and safety of food products.

U.S. Fire Tube Low-Temperature Industrial Boiler Market was valued at USD 100.8 million in 2024. The market is set to experience robust growth, driven by a significant shift towards the adoption of energy-efficient and environmentally friendly boiler systems. This transition is being propelled by a growing emphasis on sustainability and the integration of renewable energy sources, such as solar and wind, into industrial heating processes. The move towards greener technologies is becoming increasingly important as industries seek to comply with stricter environmental regulations and reduce their carbon footprint.

Major players operating in the fire tube low temperature industrial boiler industry include Thermodyne Boilers, Babcock Wanson, Victory Energy Operations, Hurst Boiler & Welding, Miura America, Babcock & Wilcox, Cleaver-Brooks, Thermex, Clayton Industries, Walchandnagar Industries, IHI Corporation, Johnston Boiler, Rentech Boilers, Fulton, EPCB Boiler, and Cleaver-Brooks. In order to strengthen their position in the fire tube low-temperature industrial boiler market, companies are adopting several key strategies. Many are focusing on technological advancements to improve the efficiency and sustainability of their boilers. This includes the development of boilers with enhanced heat exchange systems, advanced burner technologies, and integrated smart controls for better energy management.