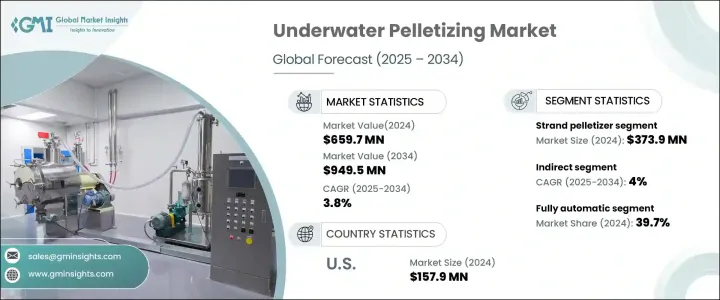

세계의 수중 펠릿화 시장은 2024년에 6억 5,970만 달러에 이르렀으며, 2025년부터 2034년에 걸쳐 CAGR 3.8%를 나타낼 것으로 예측되어 꾸준히 확대될 계획입니다.

자동차, 포장, 의료, 일렉트로닉스 등의 산업에서 고품질 플라스틱 펠릿 수요가 증가하고 있는 것이 이 성장을 뒷받침하고 있습니다. 시스템의 미래를 형성하고 정확성, 효율성 및 종합적인 비용 효율성을 향상시키고 있습니다.

지속가능성의 중시가 높아지면서 시장 확대를 더욱 뒷받침하고 있습니다. 산업계는 친환경 제조 공정으로 이동하고 있어 에너지 소비와 재료 폐기를 줄이는 고급 펠레타이징 시스템의 채용이 증가하고 있습니다. 자동차 및 전자 산업의 경량이고 내구성있는 플라스틱 부품에 대한 동향은 고성능 펠레타이징 기술에 대한 수요에 박차를 가하고 있습니다.

| 시장 범위 | |

|---|---|

| 시작 연도 | 2024년 |

| 예측 연도 | 2025-2034년 |

| 시작 금액 | 6억 5,970만 달러 |

| 예측 금액 | 9억 4,950만 달러 |

| CAGR | 3.8% |

스트랜드 펠릿화기 분야는 2024년에 3억 7,390만 달러에 이르렀고, 2025년부터 2034년까지 연평균 복합 성장률(CAGR) 4.1%를 나타낼 것으로 예상됩니다. 이 시스템은 저점도 재료의 처리에 널리 사용되며, 용융 폴리머를 스트랜드 형태로 밀어내고 물에서 냉각하고 균일한 펠릿으로 정확하게 절단하는 합리적인 공정을 제공합니다. 산업계가 수요 증가에 대응하기 위해 생산 규모를 확대하는 가운데, 스트랜드 펠릿화기의 채용은 급증을 계속하고 있어 대규모의 제조 작업에 있어서의 신뢰성, 일관성, 코스트 효율을 보증하고 있습니다.

수중 펠릿화 시장은 직접 판매 채널과 간접 판매 채널로 나뉘며, 2024년에는 간접 판매가 55.1%의 점유율을 차지했습니다. 이 부문은 타사 유통업체, 리셀러 및 에이전트의 전략적 이점에 힘입어 2025년부터 2034년까지 연평균 4%의 성장률을 보일 것으로 예상됩니다. 간접 판매를 활용함으로써 제조업체는 직접 사업이 제한될 수 있는 지역에도 손을 넓힐 수 있어 시장에의 폭넓은 침투를 확보할 수 있습니다. 교육과 같은 전문 고객 지원 서비스에 대한 합리적인 액세스를 제공합니다. 간접 판매의 효율성은 공급망의 유동성을 높이고 물류 장애물을 줄이는 동시에 다양한 세계 시장에서 신뢰할 수있는 제품 공급을 보장합니다.

미국의 수중 펠릿화 시장은 2024년에 1억 5,790만 달러에 이르렀고, 2025년부터 2034년까지 연평균 복합 성장률(CAGR) 3.9%를 나타낼 것으로 보입니다. 자동차, 플라스틱, 재활용, 제약 업계에서 프리미엄 품질의 플라스틱 펠릿에 대한 왕성한 수요가 시장 성장을 뒷받침합니다. 그 기술의 채용을 가속하고 있습니다.기업이 지속가능성과 업무 효율을 우선하는 가운데, 환경 배려형의 생산 관행을 목표로 하는 업계 전체의 동향과 일치해, 시장은 꾸준한 성장을 이루고 있습니다.

The Global Underwater Pelletizing Market reached USD 659.7 million in 2024 and is poised for steady expansion, projected to grow at a CAGR of 3.8% between 2025 and 2034. Increasing demand for high-quality plastic pellets across industries such as automotive, packaging, medical, and electronics is fueling this growth. As manufacturers push for innovation, advancements in polymer production technology are shaping the future of pelletizing systems, improving precision, efficiency, and overall cost-effectiveness. Companies are developing more energy-efficient solutions to accommodate a diverse range of materials, from conventional plastics to high-performance polymers.

Growing emphasis on sustainability is further driving market expansion. Industries are shifting toward eco-friendly manufacturing processes, increasing the adoption of advanced pelletizing systems that reduce energy consumption and material waste. Manufacturers are also integrating automation and AI-driven monitoring into pelletizing equipment, ensuring consistent pellet quality and minimizing downtime. The trend toward lightweight and durable plastic components in the automotive and electronics industries is adding momentum to the demand for high-performance pelletizing technologies. As global supply chains evolve, companies are optimizing production strategies to meet growing requirements for scalable and reliable pelletizing solutions, reinforcing the market's upward trajectory.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $659.7 Million |

| Forecast Value | $949.5 Million |

| CAGR | 3.8% |

The strand pelletizer segment reached USD 373.9 million in 2024 and is expected to expand at a CAGR of 4.1% from 2025 to 2034. These systems are widely used for processing lower-viscosity materials, delivering a streamlined process where molten polymer is extruded into strands, cooled in water, and precisely cut into uniform pellets. Their efficiency and high-throughput capabilities make them indispensable in consumer goods, automotive, and packaging sectors. As industries scale up production to meet rising demand, the adoption of strand pelletizers continues to surge, ensuring reliability, consistency, and cost efficiency in large-scale manufacturing operations.

The underwater pelletizing market is divided into direct and indirect sales channels, with indirect sales holding a 55.1% share in 2024. This segment is anticipated to grow at a CAGR of 4% between 2025 and 2034, driven by the strategic advantages of third-party distributors, resellers, and agents. By leveraging indirect sales, manufacturers can expand their reach into regions where direct operations may be limited, ensuring broad market penetration. This distribution model provides streamlined access to specialized customer support services such as installation, maintenance, and training. The efficiency of indirect sales enhances supply chain fluidity, reducing logistical hurdles while ensuring reliable product availability across diverse global markets.

The U.S. underwater pelletizing market reached USD 157.9 million in 2024 and is set to grow at a CAGR of 3.9% between 2025 and 2034. Strong demand for premium-quality plastic pellets in the automotive, plastics, recycling, and pharmaceutical industries propel market growth. Regulatory initiatives aimed at reducing energy consumption and emissions in manufacturing are accelerating the adoption of advanced pelletizing technologies. As companies prioritize sustainability and operational efficiency, the market is witnessing steady growth, aligning with industry-wide trends toward environmentally conscious production practices. These factors continue to shape the evolving landscape of underwater pelletizing, driving innovation and market expansion.