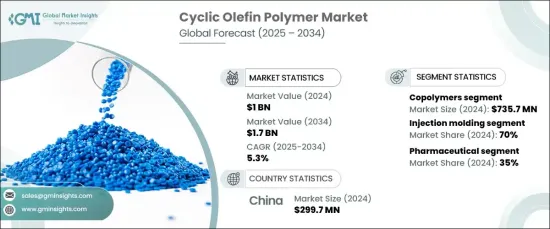

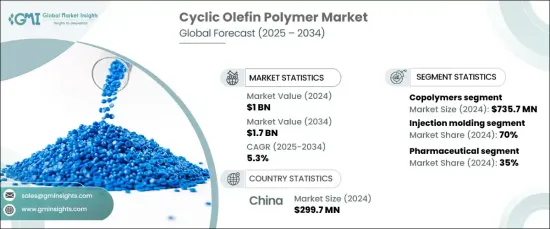

환형 올레핀 폴리머 세계 시장 규모는 2024년에 10억 달러에 달했고, 2025-2034년 5.3%의 연평균 복합 성장률(CAGR)을 보일 것으로 예상됩니다.

이러한 성장의 원동력은 COP의 높은 투명성, 내화학성, 낮은 단백질 흡착 등 우수한 재료 특성으로 다양한 산업에서 선호되고 있습니다. 포장, 의료, 제약 분야 등 COP의 다용도성은 COP의 보급에 더욱 기여하고 있습니다. 산업계가 광학 부품, 전자기기, 자동차 부품에 첨단 솔루션을 요구함에 따라 COP 수요는 계속 증가하고 있습니다.

COP는 저흡수성, 우수한 치수 안정성, 인상적인 광학 투명성 등의 우수한 특성으로 인해 큰 주목을 받고 있는 독특한 폴리머입니다. 이러한 특성으로 인해 COP는 특히 식품 및 의약품 분야에서 제품의 무결성을 유지하고 유통기한을 연장하는 데 도움이 되는 패키징 분야에서 높은 인기를 얻고 있습니다. 제약 산업에서 COP는 약물 전달 시스템, 주사기, 바이알 등의 용도로 높은 수요가 있습니다. 불활성 특성으로 인해 민감한 의약품의 내용물과 상호 작용하지 않기 때문에 제품의 안정성을 유지하는 데 매우 중요합니다.

| 시장 범위 | |

|---|---|

| 시작 연도 | 2024년 |

| 예측 연도 | 2025-2034년 |

| 시작 금액 | 10억 달러 |

| 예상 금액 | 17억 달러 |

| CAGR | 5.3% |

시장은 호모폴리머와 코폴리머로 나뉘며, 2024년에는 코폴리머가 7억 3,570만 달러로 시장을 주도했습니다. 이는 우수한 내화학성, 낮은 수분 흡수, 향상된 광학 특성을 제공하는 공중합체에 대한 수요가 증가하고 있기 때문입니다. 이러한 장점으로 인해 공중합체는 오염 및 환경 노출로부터 섬세한 제품을 보호하는 고성능 패키징 용도에서 특히 매력적인 소재가 되고 있습니다.

고리형 올레핀 폴리머 시장은 전자, 자동차, 식음료, 화학, 제약, 포장, 광학 등 다양한 최종 사용 산업에 걸쳐 있으며, 2024년에는 제약 분야가 시장의 35%를 차지할 것으로 예상되며, COP는 투명성이 높고, 추출물이 적으며, 화학물질에 대한 내성이 강해 제약 포장에 가장 적합한 소재입니다. 화학물질에 강한 특성이 있어 의약품 포장에 가장 적합한 소재입니다. 그 불활성 특성으로 인해 의약품과 의료기기가 최적의 상태로 유지되고 효능이 유지됩니다.

2024년 중국의 COP 시장은 2억 9,970만 달러로 평가되었고, 향후 몇 년동안 급성장할 것으로 예상됩니다. 중국의 확대되는 제약 및 의료 부문이 이 수요의 주요 원동력이 되고 있습니다. 이 소재의 광학 투명성, 내화학성, 정밀 성형 능력은 이러한 산업에서 귀중한 자산이 되고 있습니다. 또한, COP의 전자 및 광학 응용 분야에서의 사용은 아시아태평양에서 COP의 입지를 더욱 강화하고 있으며, 소비자용 전자제품과 첨단 의료기기 모두에서 수요가 증가하고 있습니다.

The Global Cyclic Olefin Polymer Market was valued at USD 1 billion in 2024 and is expected to experience a CAGR of 5.3% from 2025 to 2034. This growth is driven by COP's exceptional material properties, including high transparency, chemical resistance, and low protein adsorption, which make it a preferred choice in various industries. The versatility of COP in applications such as packaging, medical, and pharmaceutical sectors further contributes to its widespread adoption. As industries seek advanced solutions for optical components, electronics, and automotive parts, the demand for COP continues to rise.

COP is a unique polymer gaining significant attention due to its superior qualities, which include low water absorption, excellent dimensional stability, and impressive optical clarity. These attributes have made COP highly popular in packaging applications, especially in the food and pharmaceutical sectors, where it helps to preserve product integrity and prolong shelf life. In the pharmaceutical industry, COP is in high demand for applications like drug delivery systems, syringes, and vials. Its inert nature ensures that it does not interact with sensitive pharmaceutical contents, which is crucial for maintaining product stability.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $1 Billion |

| Forecast Value | $1.7 Billion |

| CAGR | 5.3% |

The market is divided into homopolymers and copolymers. In 2024, copolymers led the market, generating USD 735.7 million. This is due to the increasing demand for copolymers, which offer superior chemical resistance, lower water absorption, and enhanced optical properties. These advantages make them particularly attractive in high-performance packaging applications, where they protect sensitive goods from contamination and environmental exposure.

The cyclic olefin polymer market spans several end-use industries, including electronics, automotive, food and beverages, chemicals, pharmaceuticals, packaging, and optical sectors. In 2024, the pharmaceutical sector accounted for a dominant 35% share of the market. COP's qualities of high transparency, low extractables, and resistance to chemicals make it the go-to material for pharmaceutical packaging. Its inertness ensures that medications and medical devices are kept in an optimal condition, preserving their effectiveness.

In 2024, the China COP market was valued at USD 299.7 million and is set to experience rapid growth in the coming years. China's expanding pharmaceutical and healthcare sectors are key drivers of this demand. The material's optical clarity, chemical resistance, and precision molding capabilities make it a valuable asset for these industries. Furthermore, COP's use in electronics and optical applications is further propelling its presence in the Asia Pacific, with growing demand in both consumer electronics and advanced medical devices.