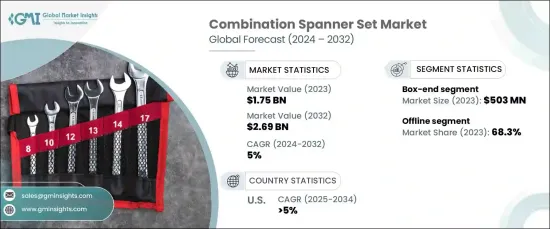

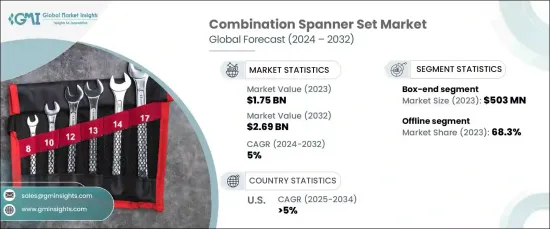

세계의 콤비네이션 스패너 세트 시장은 2023년에 17억 5,000만 달러로 평가되었고, 2024년부터 2032년까지 연평균 복합 성장률(CAGR) 5%로 성장할 것으로 예측됩니다. 이러한 공구에 대한 수요의 급증은 산업계와 개인 사용자 모두가 범용성과 다양한 작업의 효율성으로 인해 이러한 공구에 대한 의존도를 높이고 있기 때문입니다. 팬데믹 기간 동안 산업은 새로운 작업 과제에 적응하여 콤비네이션 스패너 세트가 필수적이었습니다. 안전 규제가 강화되고 작업 효율이 더욱 중요해지면서 이러한 도구에 대한 투자가 크게 증가하고 있습니다. 제조업과 서비스업에서 중소기업이 늘어나면서 효율적이고 고성능인 스패너 세트에 대한 요구가 커지고 있습니다. 프로도 DIY 애호가도 여러 유형의 패스너를 취급할 수 있어, 유지보수와 수리의 효율이 향상되기 때문에 이러한 공구를 선택하는 것이 증가하고 있습니다.

콤비네이션 스패너 세트는 현재 산업 환경과 주거 환경 모두에서 필수적인 것으로 간주되고 있으며, 다양한 유형의 패스너로 작업할 수 있는 유연성을 사용자에게 제공합니다. 작업을 빠르고 정확하게 완료하는 효율성은 생산성 향상을 목표로 하는 전문가에게 선호되는 선택입니다. 이 수요 증가는 신뢰성과 사용 편의성을 결합한 공구로의 이동과 관련이 있습니다. 자동화 및 고정밀 공구의 요구가 증가함에 따라 특히 자동차, 제조 및 건설과 같은 업계에서 콤비네이션 스패너 수요가 더욱 높아지고 있습니다.

| 시장 범위 | |

|---|---|

| 시작 연도 | 2023년 |

| 예측 연도 | 2024-2032년 |

| 시작 금액 | 17억 5,000만 달러 |

| 예측 금액 | 26억 9,000만 달러 |

| CAGR | 5% |

박스 엔드 콤비네이션 스패너는 2023년에 약 5억 300만 달러의 수익을 차지하였고, 2032년까지의 CAGR은 약 5.5%로 예측됩니다. 이러한 공구는 패스너를 조이거나 느슨하게 하는 데 필수적이며 타의 추종을 불허하는 다용도를 제공합니다. 인기가 높아지고 있는 이유는 자동차 및 제조업을 중심으로 다양한 분야에서 유지보수 및 수리에 대한 수요가 계속되고 있기 때문입니다. 인체 공학적 기능과 내구성 향상을 포함한 설계 혁신으로 박스 엔드 스패너는 신뢰성과 정확성이 필요한 전문가에게 최적의 선택이 되었습니다.

콤비네이션 스패너 세트의 오프라인 판매 부문은 2023년에 약 68.3%의 점유율로 시장을 선도하였고, 이 추세는 2024년부터 2032년까지 매년 4.4%의 성장률로 지속될 것으로 예상됩니다. 소비자는 제품의 품질을 직접 확인할 수 있는 실제 매장에서 공구를 구입하는 것을 선호합니다. 또, 점포에서의 쇼핑은 곧바로 이용할 수 있어, 개별 대응도 가능해, 고객 경험을 향상시키고 있습니다. 지식이 풍부한 판매 담당자는 고객의 요구에 맞는 최적의 공구를 제안합니다. 수리 및 유지 보수와 같은 애프터 서비스의 부가가치는 오프라인 쇼핑의 매력을 높이고 충성심을 키우고 반복을 촉진합니다.

미국에서는 콤비네이션 스패너 세트 시장이 2023년에 3억 8,030만 달러를 넘어섰고, 2024년부터 2032년까지 CAGR 5% 이상으로 성장할 것으로 예측되고 있습니다. 이 성장의 원동력이 되고 있는 것은 이 나라 대규모 소비자층에 있어서 다용도로 효율적인 공구에 대한 수요입니다. 미국 시장은 견조한 제조 부문, 최첨단 제품 혁신, 첨단 기술 통합의 이점을 누리고 있습니다. 고급 공구로의 이동은 보다 높은 정밀도와 엄격한 안전 규정 준수의 필요성에 의해 촉진됩니다. 산업이 계속 진화함에 따라 내구성, 정밀도, 사용 편의성을 결합한 콤비네이션 스패너 세트에 대한 수요가 높아질 것으로 예상됩니다.

The Global Combination Spanner Set Market was valued at USD 1.75 billion in 2023 and is projected to grow at a CAGR of 5% between 2024 and 2032. The surge in demand for these tools comes as both industries and individual users increasingly rely on them for their versatility and efficiency in various tasks. During the pandemic, industries adapted to new operational challenges, making combination spanner sets indispensable. With safety regulations tightening and a greater focus on operational efficiency, there has been a significant increase in investments in these tools. As more small and medium-sized businesses emerge in the manufacturing and service sectors, the need for efficient and high-performing spanner sets has grown. Professionals and DIY enthusiasts alike are increasingly choosing these tools due to their capability to handle multiple types of fasteners, improving maintenance and repair efficiency.

Combination spanner sets are now considered essential in both industrial and residential environments, providing users with the flexibility to work with a wide range of fasteners. Their efficiency in completing tasks quickly and accurately has made them a preferred choice for professionals looking to enhance productivity. This growing demand is also linked to the shift toward tools that combine reliability with ease of use. The rise in automation and high-precision tool needs further drives the demand for combination spanners, particularly in industries such as automotive, manufacturing, and construction.

| Market Scope | |

|---|---|

| Start Year | 2023 |

| Forecast Year | 2024-2032 |

| Start Value | $1.75 Billion |

| Forecast Value | $2.69 Billion |

| CAGR | 5% |

Box-end combination spanners, accounting for approximately USD 503 million in revenue in 2023, are forecasted to grow at a CAGR of about 5.5% through 2032. These tools are essential for tightening or loosening fasteners, offering unmatched versatility. Their increasing popularity is driven by the ongoing demand for maintenance and repair across various sectors, particularly automotive and manufacturing. Innovations in design, such as ergonomic features and enhanced durability, are making box-end spanners the go-to choice for professionals who require reliability and precision.

The offline sales segment for combination spanner sets led the market with a share of around 68.3% in 2023, and this trend is expected to continue with a growth rate of 4.4% annually from 2024 to 2032. Consumers increasingly prefer purchasing tools from physical stores where they can inspect product quality in person, ensuring satisfaction with their purchase. In-store shopping also offers immediate availability and personalized assistance, which enhances the customer experience. Knowledgeable sales representatives provide tailored recommendations, ensuring customers select the best tools for their needs. The added value of after-sales services, such as repairs and maintenance, boosts the appeal of offline shopping, fostering loyalty and encouraging repeat business.

In the U.S., the combination spanner set market exceeded USD 380.3 million in 2023 and is projected to grow at a CAGR of over 5% between 2024 and 2032. This growth is driven by the demand for versatile and efficient tools within the country's large consumer base. The U.S. market benefits from a robust manufacturing sector, cutting-edge product innovations, and the integration of advanced technology. This shift towards advanced tools is fueled by the need for higher precision and the adherence to stringent safety regulations. As industries continue to evolve, the demand for combination spanner sets that combine durability, precision, and ease of use is expected to rise.